- Introduction to the Process and Importance of Peel Walnut

- Key Technical Advantages in Walnut Processing

- Industry Manufacturer Analysis and Comparative Study

- Custom Solutions for Diverse Client Requirements

- Applications and Real-World Case Studies Featuring Peel Walnut

- Market Analysis: Trends, Data, and Pricing Insights

- Conclusion: Maximizing Value with Peel Walnut in Today’s Market

(peel walnut)

Introduction: The Role of Peel Walnut in Nut Processing Industries

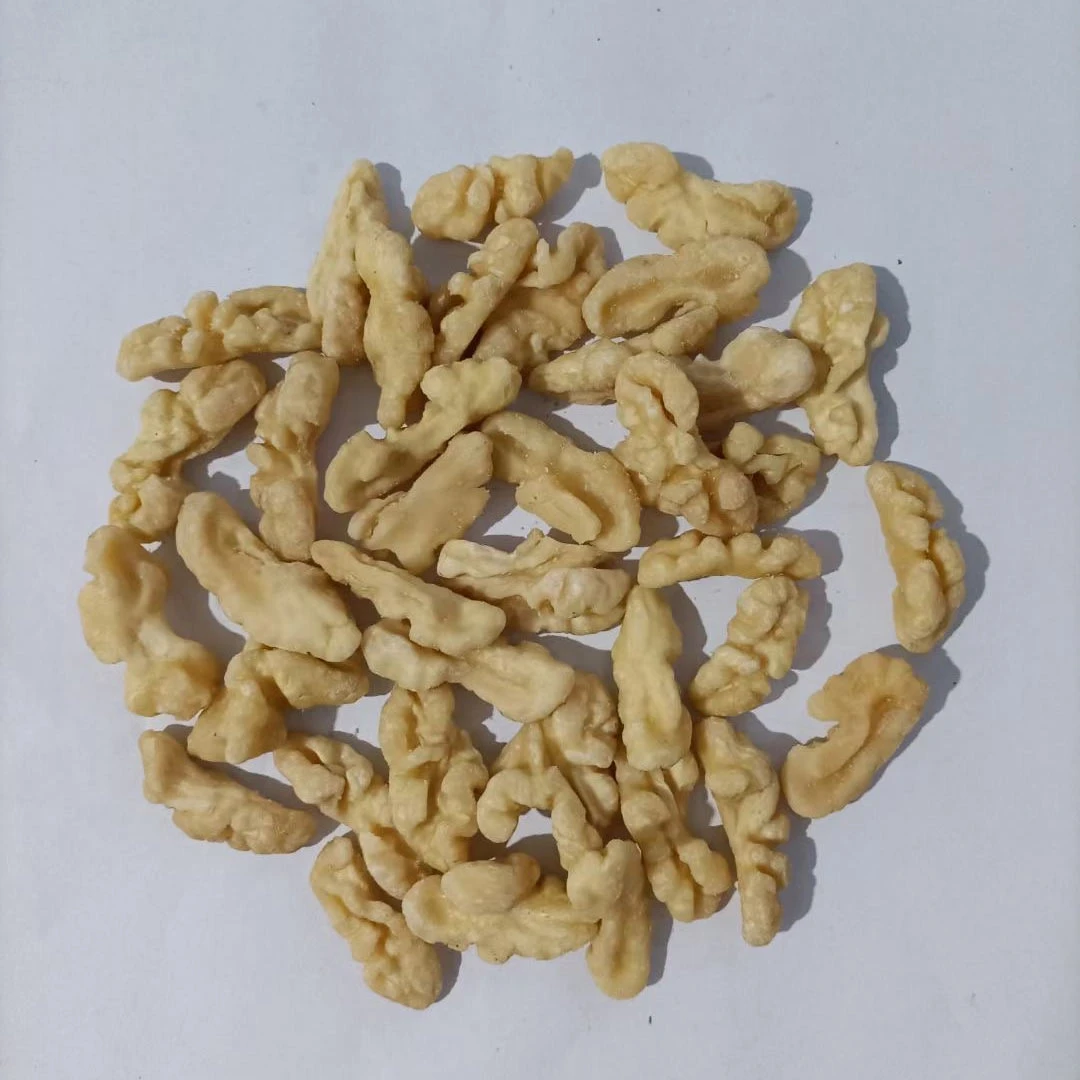

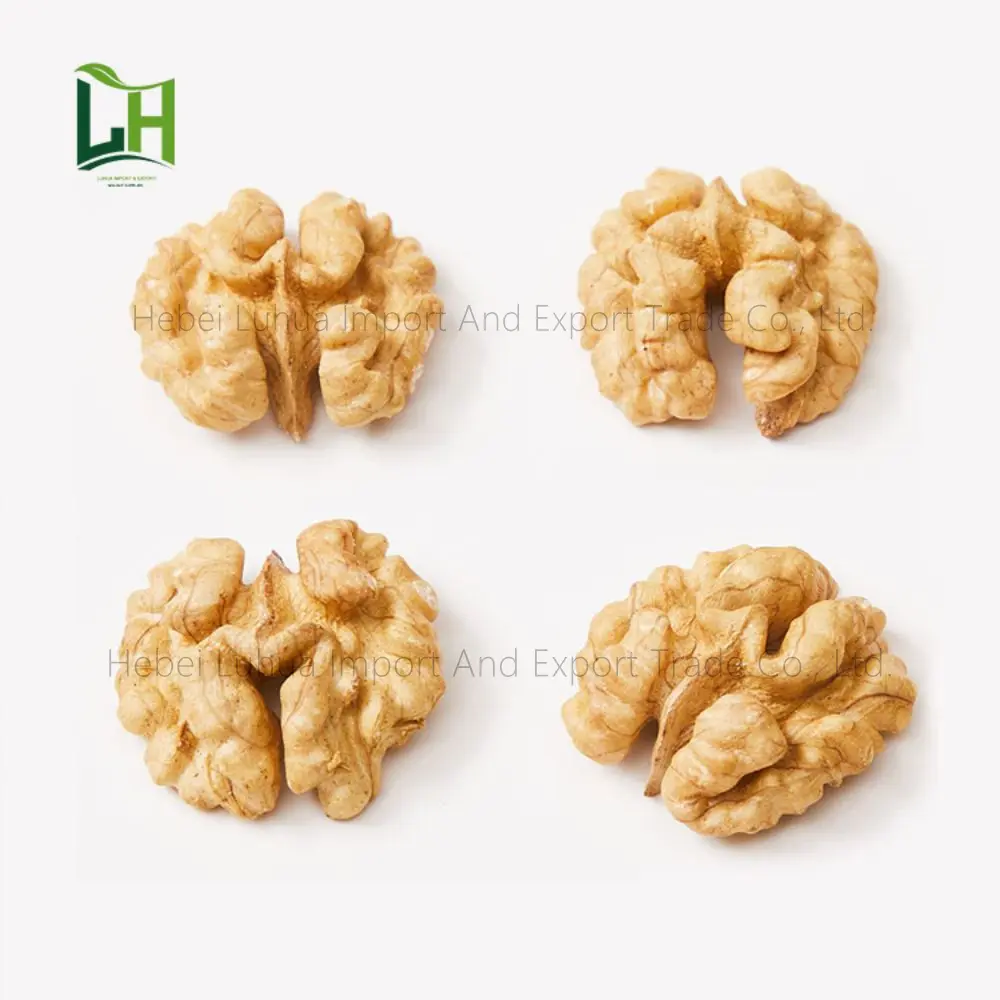

In recent years, there has been a significant shift in the nut processing sector, with

peel walnut

standing out as a pivotal process. Modern consumers demand high-quality, ready-to-eat nuts,

free from shells and with minimal bitterness, a property achieved through effective peeling practices.

The ability to peel walnuts efficiently not only enhances taste and visual appeal but also delivers a product

that retains nutritional integrity. Global demand for processed walnuts stands at over 850,000 metric tons per year,

a substantial portion directly resulting from advances in peeling technologies.

As international market demand rises, especially in North America and Western Europe, walnut producers have had

to innovate consistently to stay ahead. This article will detail the technical superiority of newer peeling methods,

compare leading manufacturers, explore customizations, analyze application cases, and break down current

walnut rate per kg to help stakeholders and enthusiasts fully grasp their investment's value.

Technical Advancements Shaping the Peel Walnut Process

The quality of a peeled walnut hinges largely on the sophistication of the peeling process. Modern processing lines have adopted non-destructive, water-based washing combined with air-knife technology, which delivers up to 99% shell removal without compromising the natural skin. The main metrics that matter to operators are peeling efficiency, kernel integrity, percentage of complete halves retrieved, and speed of throughput. For instance, state-of-the-art peeling systems can process upwards of 1,200 kg per hour, with an average intact kernel rate of 93% and a breakage rate of less than 2%. Advances such as low-pressure steam chambers and vibratory sieves further reduce residual shell fragments, minimizing the labor required for quality assurance. These technological improvements not only catalyze productivity but also drive down unit costs, directly influencing the competitive landscape of walnut processing worldwide. Quality control, managed via automated sensors and high-speed cameras, ensures only the best kernels reach the packaging stage, while waste solids are efficiently diverted for other food or industrial uses, further maximizing operational efficiency.

Comparing Manufacturers: Who Leads in Walnut Peeling Technology?

A vital consideration for processors is choosing the right manufacturer to meet specific goals. Below is a comprehensive comparison of three leading machinery producers based on performance metrics and client support, displayed in the following table:

| Manufacturer | Hourly Capacity (kg) | Peeling Efficiency (%) | Intact Kernel Rate (%) | Automation Level | Warranty (years) | Global Support |

|---|---|---|---|---|---|---|

| WalTech Solutions | 1200 | 98 | 93 | Full | 3 | 24/7 |

| Nutex Engineering | 900 | 95 | 89 | Semi | 2 | Business Hours |

| Global Peel Inc. | 1500 | 97.5 | 94 | Full | 2 | 24/7 |

The data demonstrates that manufacturers offering full automation, such as WalTech Solutions and Global Peel Inc., outpace their competitors in capacity and intact kernel preservation. Additionally, global support and warranty periods are crucial considerations for continuous operations since downtime translates to missed market opportunities. Investment in superior machinery may command a premium but pays off via long-term output consistency and reduced operational disruptions.

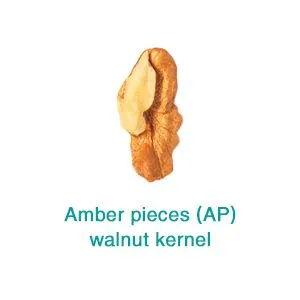

Custom Solutions: Meeting Specific Peel Walnut Needs

Modern walnut processors rarely adopt one-size-fits-all solutions. The rise in boutique and specialty food markets has driven demand for customization, ranging from small-batch artisan peeling to high-volume industrial lines. Customization may include kernel moisture control, tailored peeling pressure for different walnut cultivars, or modular integration with existing cleaning, sorting, and vacuum packaging units. For instance, an organic nut processor might request a steam-only system without any chemical pre-treatment for a niche health-oriented market, while a major snack food producer would prioritize throughput and automated defect rejection. Market leaders in machine manufacturing now offer remote configuration, real-time traceability, and predictive maintenance via IoT interfaces. This not only minimizes machine downtime but empowers operators to steer processing towards optimal efficiency regardless of feedstock variability. Flexible implementation ensures that even smaller facilities can adopt global best practices to boost their market share and improve the overall walnut rate per kg they command.

Real-World Applications and Case Studies

The practical impact of engineering excellence in peel walnut processing is apparent in various commercial settings. Leading European premium confectionery brands, for example, insist on kernels free from skin residue or shell fragments, as even minor flaws can affect the final product’s taste and value perception. In a notable case, a California-based walnut cooperative upgraded their facility with high-efficiency peelers, resulting in a 15% reduction in kernel breakage and a 12% uplift in export revenues within 18 months. Additionally, Asian snack brands, which process upwards of 3,500 kg of walnuts daily, have transitioned to automated lines, reducing labor costs by nearly 30% and cutting order lead times by 40%. These results are further mirrored in the organic market, where adherence to chemical-free peeling allowed a Turkish exporter to penetrate Scandinavian supermarket chains, citing superior peeling uniformity and food safety credentials as key differentiators. Across these settings, the shared outcomes include higher rates of customer satisfaction, improved shelf appeal, and tangible economic gains.

Market Overview: Trends, Data, and Pricing with Walnut Rate per kg Analysis

The global walnut industry is currently valued at approximately $8.5 billion, with a compound annual growth rate (CAGR) of 6.9% projected through 2028. The peel walnut segment, in particular, benefits from growing demand in bakery, confectionery, snack, and nutrition markets. From a cost perspective, the average walnut rate per kg has fluctuated between $3.40 and $4.60 in the past 18 months, influenced by crop yields, labor conditions, and processing efficiencies. In premium export markets, walnut rate 1 kg for fully peeled, large halves sometimes surpasses $6.00, especially for organic and traceable lots. The payoff from investing in advanced peeling technology becomes apparent when considering the reduction in waste factors (average decrease from 8% to 3%) and the ability to produce visually uniform product grades demanded by top-tier buyers. Market forecasting indicates that rising consumer awareness and expanding applications in plant-based protein will further drive up prices and reward innovation.

Conclusion: The Strategic Value of Peel Walnut for Modern Processors

The journey towards mastering peel walnut technology is ultimately about maximizing kernel value and business resilience in a rapidly evolving global marketplace. Embracing leading-edge machinery, tailored solutions, and data-driven process controls enables producers to consistently achieve industry-leading yields and quality benchmarks. As walnut rate per kg continues to reflect both the cost of production and consumer preference for convenience, those at the forefront of processing innovation will secure premium market access and sustained profitability. By uniting technical prowess, custom adaptability, and a relentless focus on quality, today's processors transform what could be a commodity into a competitive advantage, ensuring their place at the heart of the evolving nut industry.

(peel walnut)

FAQS on peel walnut

Q: How do you peel a walnut effectively?

A: To peel a walnut, soak the nuts in hot water for 10 minutes, then gently crack the shell. Carefully remove the skin with your fingers or a small knife.Q: What is the current walnut rate per kg?

A: The walnut rate per kg varies by region and quality but generally ranges from $8 to $15 per kilogram. Always check the latest prices in your local market.Q: Why is it important to peel walnuts before eating?

A: Peeling walnuts removes their bitter skin, improving both the taste and texture. It also helps reduce tannin content.Q: What factors influence walnut rate 1 kg in the market?

A: The walnut rate for 1 kg depends on quality, origin, and seasonal availability. Market demand and processing methods also affect the price.Q: Can peeled walnuts be stored, and for how long?

A: Yes, peeled walnuts should be stored in an airtight container in the refrigerator. They typically remain fresh for up to six months.Post time:Jul . 06, 2025 07:56