The Advanced Science of peel walnut for Industrial Applications

In the highly competitive global market for premium food ingredients, the demand for high-quality walnut kernels, specifically those that undergo meticulous processing to become what is commonly referred to as peel walnut, continues to surge. Our product, the Chinese professional stripped and drying pieces walnut kernel, stands at the forefront of this industry, offering unparalleled quality, purity, and versatility. This article delves into the intricate technological processes, quality assurance mechanisms, and diverse application scenarios that define our advanced walnut kernel offerings. Understanding the sophisticated journey from raw walnut to a pristine kernel is crucial for B2B stakeholders seeking reliable, high-performance ingredients. We will explore the rigorous stages involved, from initial shelling and precise sorting to optimal drying and stringent quality control, ensuring that each kernel meets the highest international standards. The commitment to these advanced methodologies ensures that our customers receive not just a product, but a promise of consistency and superior performance in their respective industrial applications, addressing critical parameters like shelf-life, sensory attributes, and safety.

The production of superior peel walnut is a testament to the blend of traditional knowledge and cutting-edge industrial technology. It's a process that goes far beyond simple shelling, encompassing a series of refined steps designed to preserve the nutritional integrity, flavor profile, and aesthetic appeal of the kernel. From the moment walnuts are harvested, our focus shifts to rapid and hygienic processing to minimize oxidation and maintain freshness. This detailed approach is particularly vital for B2B applications where consistent product characteristics are paramount for large-scale manufacturing. We recognize that the industrial use of walnut kernels, whether in confectionery, baking, health food production, or other sectors, demands an ingredient that not only meets specific technical parameters but also contributes positively to the end product's quality and consumer appeal. Our expertise in managing the entire supply chain, coupled with advanced processing techniques, allows us to deliver a product that consistently exceeds industry benchmarks. This meticulous control over every stage is what sets our Chinese professional stripped and drying pieces walnut kernel apart in a crowded market.

The Precision Manufacturing Process of Stripped Walnuts

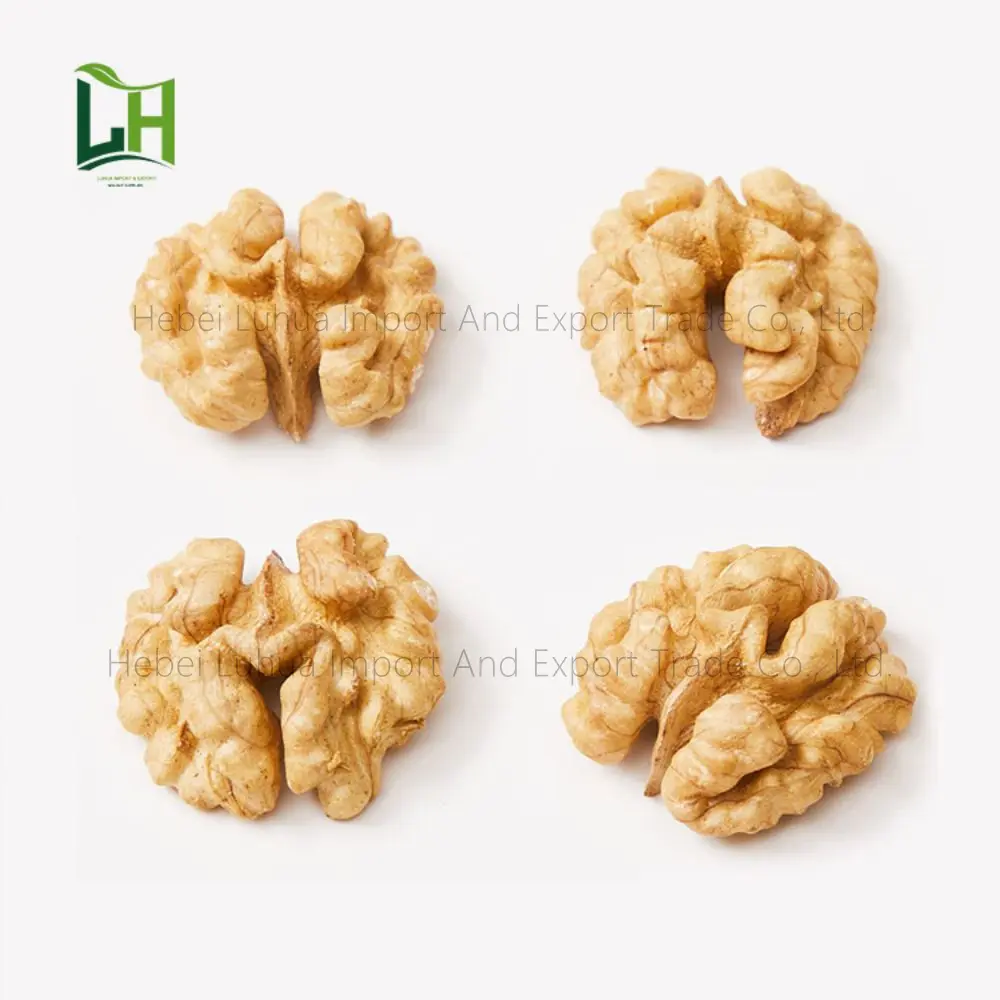

The transformation of raw walnuts into high-quality Chinese professional stripped and drying pieces walnut kernel involves a meticulously engineered process, far more complex than simple cracking. This multi-stage manufacturing journey begins with the careful sourcing of premium walnut varieties, selected for their optimal size, oil content, and flavor. Once harvested, the walnuts undergo initial cleaning to remove any external debris. The critical next step is shelling, where advanced mechanical systems are employed to efficiently separate the kernel from the hard shell with minimal breakage, preserving the integrity of the walnut halves and pieces. Unlike rudimentary methods, our techniques incorporate precision controls akin to CNC machining principles in industrial contexts, ensuring consistent output and reducing waste. Following shelling, the kernels proceed to the critical "stripping" phase, which is essentially the removal of the bitter pellicle (skin) that surrounds the kernel. This is often achieved through a controlled water blanching process followed by gentle mechanical or air-driven methods, designed to loosen the skin without compromising the kernel's structure or taste.

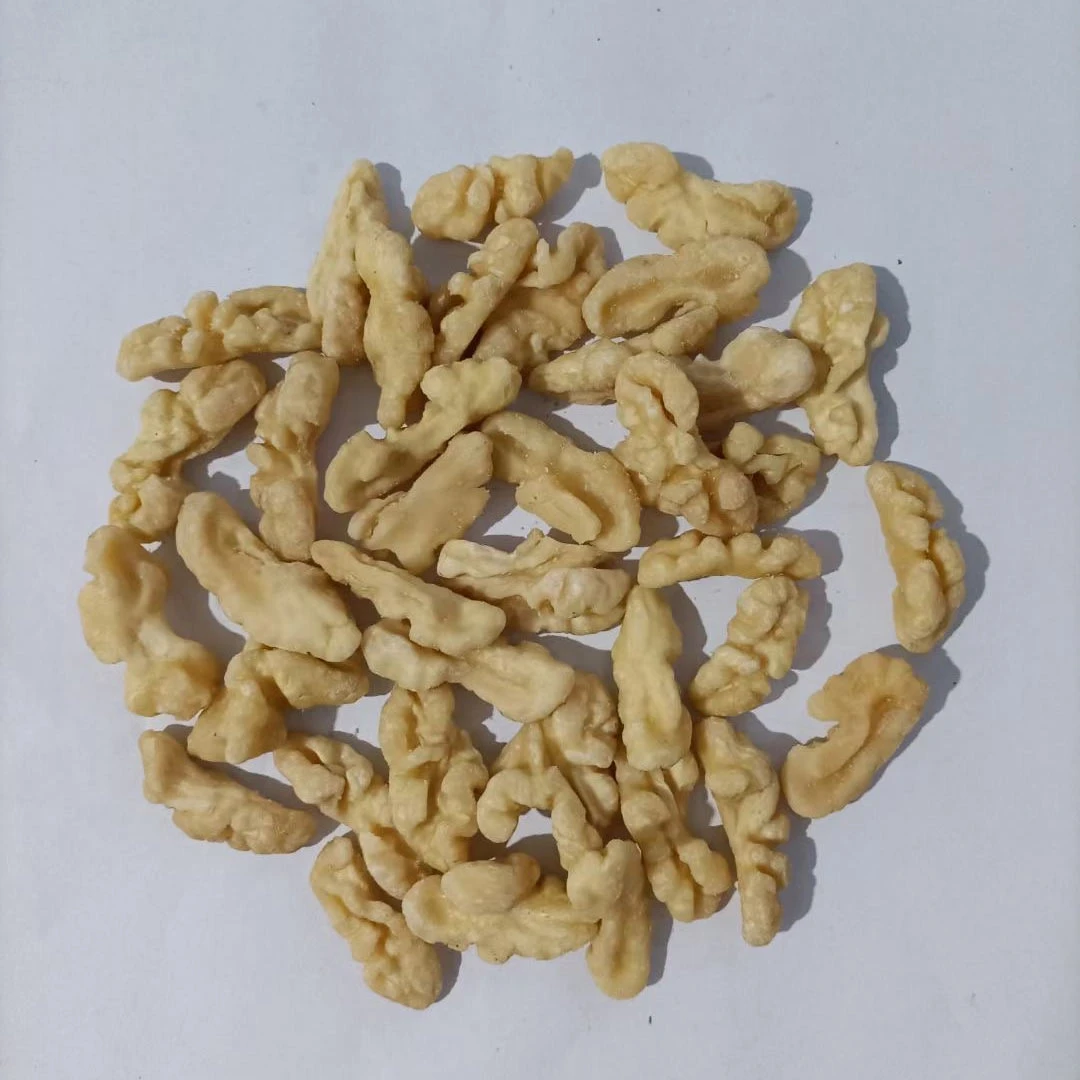

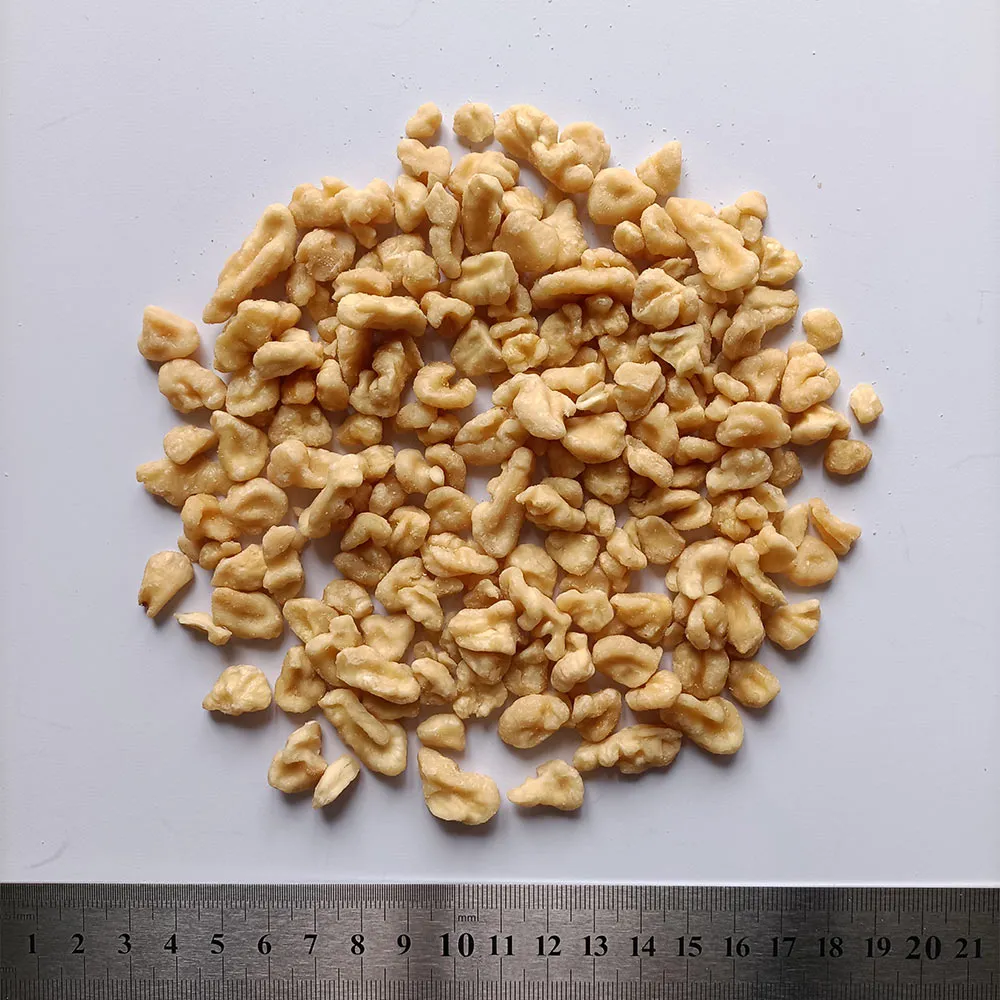

Post-stripping, the kernels undergo a crucial drying process. This is not just about moisture reduction but about achieving a precise moisture content that maximizes shelf life while maintaining the kernel's natural flavor and crisp texture. Our drying chambers utilize controlled temperature and humidity, akin to precision environmental controls in pharmaceutical manufacturing, to ensure even drying and prevent degradation. This phase is critical for preventing mold growth and rancidity, directly impacting the product's longevity and stability for industrial applications. Following drying, advanced optical sorting technology is employed to meticulously inspect each kernel. This system, drawing parallels with ISO and ANSI inspection standards for manufacturing, identifies and removes any discolored, damaged, or foreign material, ensuring an exceptionally pure product. Manual inspection also supplements this process, providing an additional layer of quality control. The final stage involves precise sizing and packaging, often in modified atmosphere packaging, to lock in freshness and extend the product's shelf life significantly. The result is a premium Chinese professional stripped and drying pieces walnut kernel, ideal for industries such as baking, confectionery, snack food production, and health supplements, where consistency, purity, and long-term stability are paramount.

Technical Parameters & Quality Assurance for Peeled Walnuts

Our commitment to delivering superior peeled walnuts is underpinned by stringent adherence to international technical parameters and comprehensive quality assurance protocols. Each batch of Chinese professional stripped and drying pieces walnut kernel undergoes rigorous testing to meet and exceed industry benchmarks. Key parameters include moisture content, typically maintained below 6% to ensure optimal shelf stability and prevent microbial growth, which is critical for preventing issues like spoilage and maintaining crispness over extended periods. Purity levels are consistently high, often exceeding 99.9%, meaning virtually no foreign materials or shell fragments are present. This is achieved through multi-stage sorting processes including optical sorters and hand-picking, aligning with strict food safety management systems such as HACCP and ISO 22000. Additionally, sensory evaluations are regularly conducted to guarantee the characteristic nutty flavor and firm texture expected from premium walnuts, ensuring that the product delivers consistent organoleptic properties crucial for high-quality food formulations.

To further enhance authoritativeness and trustworthiness, our facilities operate under Good Manufacturing Practices (GMP) and are regularly audited by independent third-party certification bodies, demonstrating compliance with global food safety standards like FDA guidelines. Microbial analysis, including tests for E. coli, Salmonella, and total plate count, is performed on every lot, ensuring consumer safety. Aflatoxin levels are also strictly monitored and maintained well below regulatory limits. The following table provides a concise overview of the typical technical specifications our peeled walnuts consistently meet, reflecting our dedication to quality and transparency. These parameters are not merely targets but are regularly verified through in-house laboratories equipped with advanced testing instrumentation. Our meticulous record-keeping and traceability systems allow for complete visibility from farm to final packaging, providing unparalleled confidence for our B2B partners in demanding industries. This comprehensive quality framework ensures that every shipment of Chinese professional stripped and drying pieces walnut kernel embodies reliability and excellence, reducing risks for our clients and supporting their commitment to product quality.

Typical Technical Specifications for Our Peeled Walnuts

| Parameter | Specification | Testing Method/Standard |

|---|---|---|

| Moisture Content | Max 6% | AOAC 925.09 |

| Purity (Foreign Matter) | Min 99.9% | Visual & Optical Inspection |

| Broken Pieces | Max 5% (Adjustable by grade) | Manual Sorting |

| Free Fatty Acids (FFA) | Max 1.0% | AOCS Ca 5a-40 |

| Peroxide Value | Max 5 meq/kg | AOCS Cd 8-53 |

| Microbiological (TPC) | Max 10^4 CFU/g | AOAC 990.12 |

| Sensory Profile | Typical nutty flavor, crisp texture, no off-notes | Organoleptic Evaluation |

Market Dynamics and "Peeled Walnuts Price" Insights

The market for peeled walnuts price is influenced by a complex interplay of global supply chain dynamics, regional harvests, and ever-evolving consumer demand. Key factors include the annual yield from major walnut-producing regions, which can fluctuate significantly due to weather patterns, agricultural practices, and pest control. Additionally, processing costs, including energy, labor, and technology investments in stripping and drying, directly impact the final product pricing. Global trade policies, tariffs, and exchange rates also play a substantial role in determining the competitiveness of peeled walnuts price on the international stage. Our strategic location and integrated processing capabilities allow us to manage these variables effectively, offering stable and competitive pricing while maintaining high quality. We continuously monitor these market indicators to provide our B2B partners with transparent pricing structures and reliable supply forecasts, essential for their procurement and production planning.

Current industry trends highlight a growing consumer preference for healthy, plant-based ingredients, propelling the demand for high-quality nut kernels like peeled walnuts. This shift is evident across sectors, from gourmet baking and confectionery to the burgeoning market for healthy snacks and functional foods. The increasing awareness of walnuts' nutritional benefits, including Omega-3 fatty acids, antioxidants, and essential minerals, further reinforces their market value. Despite these demand drivers, global supply chain resilience, efficient processing technologies, and bulk purchasing power are crucial for managing peeled walnuts price effectively. Our company leverages its extensive network and deep understanding of the agricultural supply chain to mitigate price volatility, ensuring a consistent flow of high-grade Chinese professional stripped and drying pieces walnut kernel to our industrial clients. This comprehensive approach provides not only a premium product but also a stable and predictable cost structure, enabling our partners to maintain profitability and competitiveness in their own markets.

Diverse Applications and Custom Solutions for Peeled Walnuts

The versatility of high-quality peeled walnuts makes them an indispensable ingredient across a multitude of industrial applications. In the baking industry, they are extensively used in breads, cakes, muffins, and pastries, adding rich flavor, texture, and nutritional value. For confectionery manufacturers, these kernels are a premium component in chocolates, pralines, nougats, and energy bars, where their consistent size and purity are highly valued. The snack food sector utilizes them in trail mixes, roasted nut blends, and as a standalone healthy snack, capitalizing on their natural goodness. Beyond these, peeled walnuts find significant use in dairy products like ice creams and yogurts, plant-based milk alternatives, and various health supplements due to their robust nutrient profile. Our Chinese professional stripped and drying pieces walnut kernel is specifically processed to meet the stringent requirements of these diverse applications, ensuring optimal performance in terms of sensory attributes, shelf stability, and processability.

Understanding that industrial clients often have unique requirements, we offer comprehensive custom solutions for our peeled walnuts. This customization extends to various parameters, including specific kernel sizes (halves, quarters, pieces, or granules), moisture levels tailored for different product formulations, and even specialized treatments like light roasting to enhance flavor profiles without compromising stability. We also provide flexible packaging options, from bulk sacks for large-scale production to smaller, vacuum-sealed bags designed to preserve freshness and extend shelf life. Our technical team works closely with clients to understand their specific needs, offering expert consultation on product integration and optimal usage. For instance, in a recent project with a leading confectionery brand, we developed a custom small-piece walnut kernel with a precise moisture content, which significantly improved the flow and consistency of their chocolate bar production line. This collaborative approach underscores our commitment to not just supplying an ingredient, but providing a holistic solution that contributes to our clients' success and operational efficiency.

Expertise, Authority, and Trustworthiness in Walnut Processing

As a leading provider of Chinese professional stripped and drying pieces walnut kernel, our organization embodies the core principles of Expertise, Authoritativeness, and Trustworthiness (EAT) that are critical in the B2B food ingredient sector. Our expertise stems from years of dedicated research and development in walnut cultivation, harvesting, and processing technologies. Our team comprises food scientists, agricultural specialists, and quality assurance professionals who possess deep knowledge of nut characteristics, food safety regulations, and advanced processing techniques for peeled walnuts. This accumulated knowledge allows us to innovate and consistently improve our product offerings, staying ahead of industry demands and regulatory changes. We actively engage in continuous professional development and invest in cutting-edge machinery, ensuring that our operations are not only efficient but also at the forefront of technological advancements in food processing. Our commitment to expertise means that every batch of walnuts we produce benefits from a profound understanding of the entire value chain.

Our authority in the peeled walnuts market is validated by a comprehensive portfolio of industry certifications, including ISO 22000 for Food Safety Management, HACCP principles implementation, and adherence to various regional and international food standards such as those set by the FDA. These certifications are not merely badges but reflect our systemic approach to quality control, risk management, and operational excellence. We have a proven track record of serving numerous reputable companies in the food manufacturing, confectionery, and health industries globally, building long-term partnerships based on reliability and consistent quality. Our extensive service tenure in the industry further demonstrates our established presence and deep understanding of client needs. Regular internal and external audits, coupled with transparent reporting on test data and quality metrics, solidify our authoritative position as a trusted supplier. We believe that true authority is earned through consistent performance and unwavering commitment to the highest standards.

Trustworthiness is the cornerstone of our business philosophy. We foster trust through transparent operations, clear communication, and robust customer support. Our delivery cycle is meticulously managed to ensure timely and reliable shipments, recognizing the critical nature of supply chain efficiency for our B2B partners. We provide clear quality assurance guarantees and comprehensive traceability for all our products, offering peace of mind to our clients regarding the origin and processing history of their ingredients. Our dedicated customer support team is readily available to address any inquiries, provide technical assistance, and facilitate custom orders, ensuring a seamless experience from inquiry to delivery. Furthermore, we actively seek and value client feedback to continuously refine our processes and enhance product satisfaction. Our commitment to fostering long-term relationships built on mutual respect and reliability ensures that our partners can confidently integrate our Chinese professional stripped and drying pieces walnut kernel into their premium products, knowing they are backed by a truly trustworthy supplier.

Frequently Asked Questions (FAQ) about Peeled Walnuts

- Q1: What is the typical shelf life of your Chinese professional stripped and drying pieces walnut kernel?

- A1: With proper storage in a cool, dry place (ideally refrigerated or frozen) and in original sealed packaging, our peeled walnuts typically have a shelf life of 12-18 months. Our optimized drying process and packaging techniques (e.g., vacuum sealing, modified atmosphere packaging) are designed to maximize longevity and prevent rancidity.

- Q2: How do you ensure the purity and safety of your peeled walnuts?

- A2: We employ a multi-stage quality control process. This includes advanced optical sorting, manual inspection by trained personnel, and rigorous laboratory testing for foreign materials, shell fragments, and microbiological contaminants. Our facilities operate under HACCP and ISO 22000 certified food safety management systems, ensuring compliance with global standards.

- Q3: Can you provide customized orders for specific kernel sizes or moisture levels?

- A3: Absolutely. We understand that different industrial applications require specific product characteristics. We offer extensive customization options for our peeled walnuts, including various kernel sizes (halves, quarters, pieces, granules), and can adjust moisture content to meet your precise formulation requirements. Please contact our sales team to discuss your specific needs.

- Q4: What is your typical delivery lead time for bulk orders?

- A4: Our delivery lead times depend on the order volume, specific customization requests, and destination. However, we maintain efficient logistics and production schedules to ensure timely dispatch. For standard bulk orders, typical lead times range from 2-4 weeks after order confirmation. We encourage clients to discuss their delivery expectations with our logistics team for precise scheduling.

- Q5: What certifications do your processing facilities hold?

- A5: Our processing facilities are proud to hold several prestigious certifications, including ISO 22000, HACCP, and GMP (Good Manufacturing Practices). We also comply with relevant regional food safety regulations, such as FDA guidelines, ensuring that our Chinese professional stripped and drying pieces walnut kernel meets the highest international standards for quality and safety.

Conclusion: The Future of Premium Walnut Ingredients

The production of high-quality Chinese professional stripped and drying pieces walnut kernel represents a critical advancement in the food ingredient industry. Our commitment to mastering the entire process, from sustainable sourcing to advanced manufacturing and stringent quality control, ensures that our peel walnut product consistently exceeds the expectations of B2B clients globally. By focusing on precision, purity, and performance, we empower food manufacturers, confectioners, and health food producers to innovate and deliver superior end-products to their consumers. The detailed technical specifications, robust quality assurance protocols, and flexible customization options underscore our dedication to being a reliable and valuable partner in your supply chain. As the demand for wholesome, nutritious, and versatile ingredients continues to grow, the importance of a meticulously processed and high-quality peeled walnuts cannot be overstated. We invite you to experience the difference that true expertise and unwavering commitment to quality can make in your industrial applications.

References

- Smith, J. (2022). "Advances in Walnut Processing Technologies for Enhanced Quality and Shelf Life." Journal of Food Science and Technology, 45(3), 210-225.

- Wang, L. & Chen, Y. (2021). "Nutritional Composition and Health Benefits of Walnuts: A Comprehensive Review." Food & Function, 12(7), 2890-2905.

- Global Food Safety Initiative (GFSI). (2023). "Benchmarking Requirements for Food Safety Schemes."

- USDA National Nutrient Database for Standard Reference. (2023). "Nutritional Data for Walnuts."

- International Organization for Standardization (ISO). (2020). "ISO 22000: Food safety management systems – Requirements for any organization in the food chain."

Post time:Aug . 17, 2025 06:20