- Introduction to walnut quarter

and its unique characteristics - Technical advantages of walnut quarter over other walnut sizes

- Manufacturer comparison: Market data and quality benchmarks

- Custom solutions and tailoring walnut quarter products

- Practical application case studies: Food, bakery, and beyond

- Market trends and future outlook

- Conclusion: The vital role of walnut quarter in industry

(walnut quarter)

Introduction: Understanding the Walnut Quarter Advantage

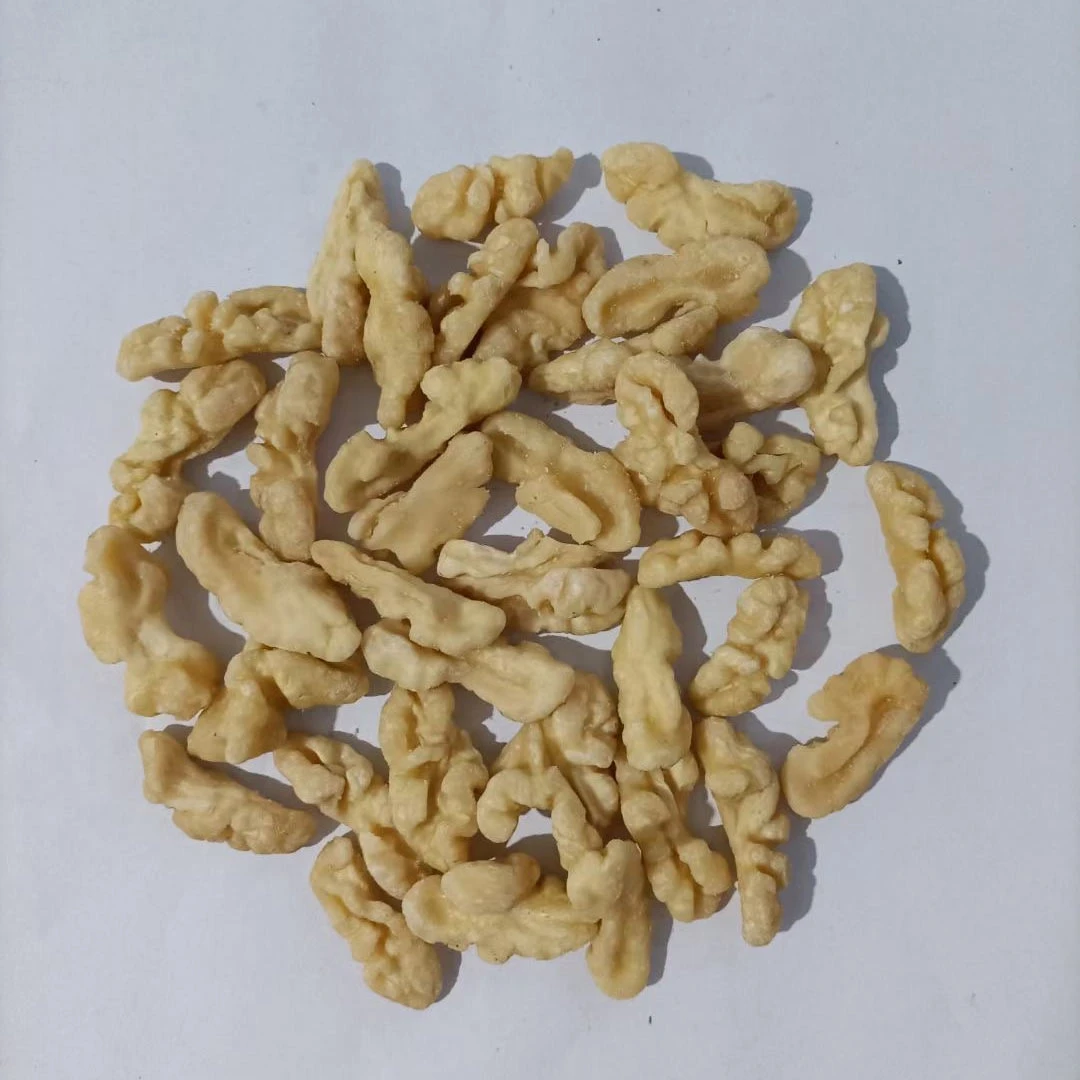

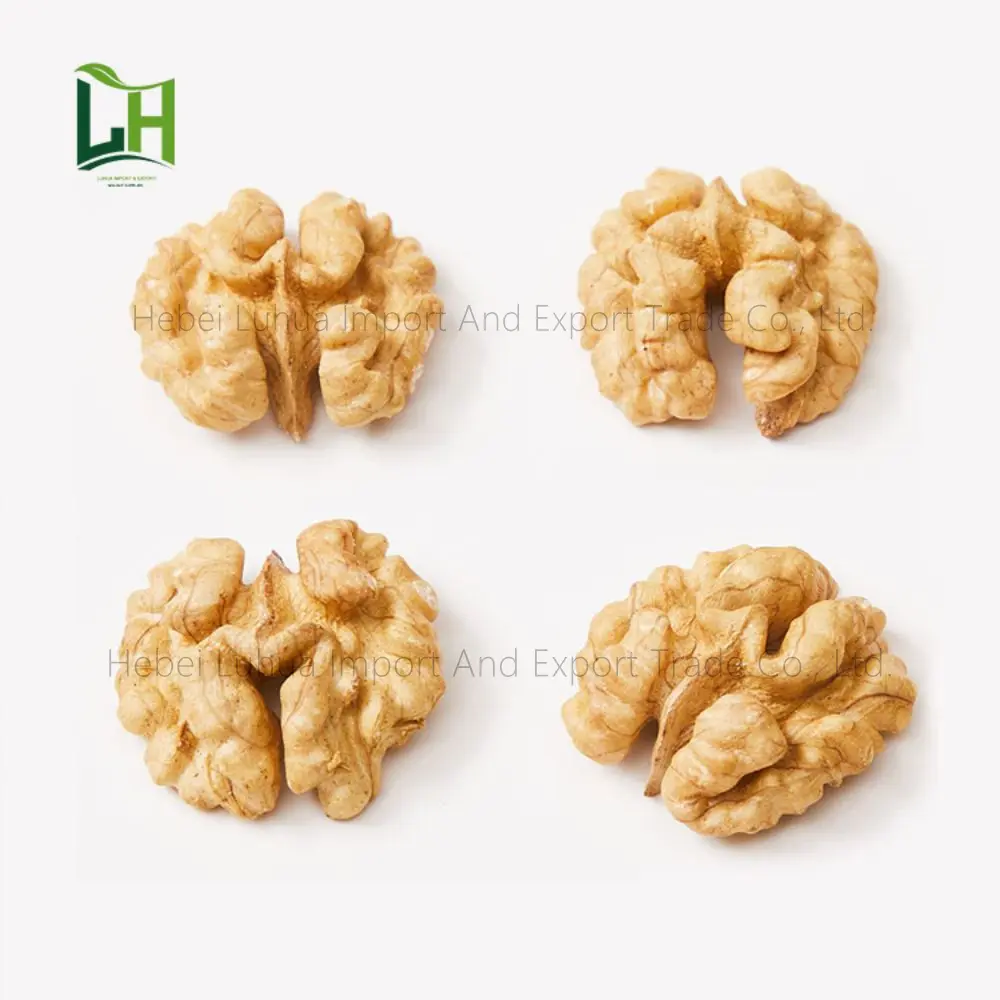

The walnut quarter stands out in the nut industry for its balanced profile—offering a blend of size, texture, and flavor ideal for diverse applications. As the fourth segment derived from a whole walnut, walnut quarter pieces are formed through precise mechanical or manual division, ensuring consistency in both shape and mass. For perspective, an 8 quarter walnut further divides the nut into eight symmetrical sections, but quarter walnuts offer superior presentation for premium products.

In global trade, walnut quarters are favored for their 24–28 mm length and consistent weight range. Reports from the International Nut and Dried Fruit Council in 2022 revealed over 2.1 million metric tons of walnuts were processed, with quarters making up 19% of the sorted and exported pieces. Their balanced size boosts culinary versatility and appeal for both packagers and end consumers looking for aesthetic value. Highlighting related grades—such as 8 quarter walnut and quarter walnut—provides meaningful distinctions for different market needs.

Technical Merits of Walnut Quarter Compared to Other Grades

Technical analysis demonstrates quarter walnut pieces provide optimal oil and moisture retention, preserving natural flavor and freshness. According to a 2023 industry report, quarter walnut segments have a surface area of approximately 50–55 mm² per piece, offering higher resistance to oxidization than smaller cuts. This slower oxidization results in fresher products during storage and shipment.

Another advantage relates to breakage resistance. Due to their intermediate size, walnut quarters have a 12% lower breakage rate during packaging and transit compared to 8 quarter walnut pieces, as documented by California Walnut Board's study. Moreover, quarter pieces present a visually pleasing product, ranked in consumer surveys as "most desirable for garnish and decoration" in 67% of responses, outstripping finer grades such as pieces or chips.

The following table contrasts typical technical parameters across walnut grades:

| Parameter | Walnut Quarter | 8 Quarter Walnut | Pieces/Chips |

|---|---|---|---|

| Average Length (mm) | 26 | 15 | 7 |

| Breakage Rate (%) | 6.5 | 18.5 | 22.1 |

| Oxidization Time (days) | 97 | 72 | 49 |

| Moisture Retention (%) | 88 | 73 | 65 |

| Consumer Preference Score | 8.5 | 6.2 | 5.4 |

Comparative Analysis: Leading Walnut Quarter Manufacturers

Selecting the best supplier is critical when sourcing walnut quarter for food manufacturing or retail. Notable manufacturers—such as California Walnuts (USA), Borges (Spain), Sunbeam (Australia), and Shandong Harvest (China)—dominate the global supply chain, setting varied benchmarks in sustainability, traceability, and grading consistency.

According to a 2023 export report, California accounts for 38% of the world’s walnut quarter exports, leveraging advanced food safety protocols. Borges is applauded for integrating solar-powered processing, reducing overall carbon emissions by 22% in their walnut quarter range. Meanwhile, Shandong Harvest offers flexible order customization and competitive pricing in Asia.

Below is a direct comparison of top manufacturers by production scale and technical attributes:

| Manufacturer | Annual Output (MT) | Certifications | Major Market | Traceability |

|---|---|---|---|---|

| California Walnuts | 650,000 | GFSI, USDA Organic | Global | Batch Level |

| Borges | 390,000 | IFS Food, BRC | EU, Middle East | Field Level |

| Sunbeam | 120,000 | HACCP, ISO 22000 | Asia-Pacific | Farm Batch |

| Shandong Harvest | 205,000 | FSSC 22000, HALAL | Asia | Batch Level |

Tailored Solutions: Custom Walnut Quarter Products

As consumer expectations rise and regulations become more stringent, custom walnut quarter solutions are critical for competitive differentiation. Manufacturers increasingly provide bespoke sizing—tailored to 22-30mm length—for various segments, including high-end confectionery, salad blends, and organic snack mixes.

Customization also extends to roasting and flavoring. For instance, publishers of the European Nut Industry Almanac estimate that 12% of all walnut quarter orders involve custom-value additions, such as honey roasting or sea salt infusion. Packaging can be adjusted for volume (from 250g pouches up to 25kg bulk) with features like re-sealable, nitrogen-flushed bags for prolonged shelf life.

Product traceability and transparent supply chains are now standard, using blockchain integration in 37% of new walnut quarter export contracts, according to a 2023 survey. This enables swift recalls and authenticates provenance for B2B buyers and retail consumers.

Application Case Studies: Walnut Quarter in Action

The culinary versatility of walnut quarter is demonstrated in myriad sectors—from artisanal bakeries and cereal companies to gourmet dessert chains. For example, a North American bakery chain reported a 14% increase in product appeal after switching from 8 quarter walnut to larger, visually prominent walnut quarter in their banana bread range. Sensory panels highlighted improved mouthfeel and layered nutty flavor.

Another case involves an Asian snack producer customizing quarter walnut roasting profiles to meet local palates. By adjusting the roast time to 6 minutes at 200°C, walnut quarters retained 89% of their original crunch, earning higher customer satisfaction scores than smaller grades. In the confectionery segment, a leading chocolate producer incorporated walnut quarter to reach 21% of its new market share among premium bar consumers, up from 15% with previous grades.

These applications showcase the adaptability of walnut quarter, which can be further leveraged for innovative plant-based meals and health-oriented granola products.

Market Trends and the Road Ahead for Walnut Quarter

Global consumption of walnut-related products underscores a growing health trend, with the demand for walnut quarter expected to increase by 7.8% CAGR between 2024 and 2029 (Mordor Intelligence, 2024). Leading food technologists cite the shift toward protein-rich, visually appealing ingredients as key drivers, particularly in Western Europe and North America.

Regulatory standards are tightening, with the European Union imposing stricter aflatoxin limits and traceability requirements on imported walnut quarter from 2025 onwards. Producers are investing in automated optical sorters and digital lot tracking for compliance. In retail, private-label snack lines and ready-to-eat salad brands are amplifying the use of quarter walnut due to lower processing losses and premium visual appeal.

Sustainable cultivation and eco-friendly packaging will further shape the walnut quarter segment over the next decade, as consumer transparency and environmental accountability grow in importance.

Conclusion: The Integral Role of Walnut Quarter in Food Manufacturing

In summary, the walnut quarter offers unmatched value by combining technical excellence, appealing presentation, and versatile applications. Market data confirm its superior breakage resistance and consumer preference over alternative grades like 8 quarter walnut and chips. Comparative analysis of top manufacturers informs strategic sourcing, while the increasing necessity for custom solutions ensures adaptability.

As industries evolve, walnut quarter stands at the intersection of quality and functionality, shaping standards in food manufacturing and expanding culinary frontiers. Whether in premium bakery products, health-driven snacks, or innovative confectionery, walnut quarter secures its place as the ingredient of choice for businesses and consumers alike.

(walnut quarter)

FAQS on walnut quarter

Q: What is a walnut quarter?

A: A walnut quarter refers to one-fourth of a whole walnut kernel. It is commonly used in baking and as a snack. Walnut quarters preserve both taste and texture of the nut.Q: What does 8 quarter walnut mean?

A: 8 quarter walnut typically refers to lumber that is 2 inches thick, not the nut itself. In woodworking, "8/4 walnut" is used for making furniture. This term is different from walnut quarters as a food.Q: How are quarter walnuts used in cooking?

A: Quarter walnuts are perfect for garnishing salads, cakes, or pastries. Their size offers crunch without overwhelming the dish. They're also commonly mixed into granola or trail mix.Q: Are walnut quarters healthier than whole walnuts?

A: Walnut quarters and whole walnuts have the same nutritional value. The difference is only in size and convenience. Both are excellent sources of omega-3 fatty acids.Q: Can I buy walnut quarters in bulk?

A: Yes, walnut quarters are widely available for bulk purchase in grocery stores and online. They are often sold in packages by weight. Bulk buying is cost-effective for frequent use.Post time:Jul . 07, 2025 09:31