Navigating the Global Market for Bulk Walnut Pieces: Trends and Opportunities

The global market for walnut pieces bulk is currently experiencing dynamic shifts driven by evolving consumer preferences, health consciousness, and a burgeoning demand across various industrial applications. A significant trend is the increasing consumer awareness regarding the nutritional benefits of walnuts, particularly their rich Omega-3 fatty acid content, antioxidants, and essential minerals, which has fueled their integration into daily diets as a healthy snack or ingredient. This heightened health consciousness aligns perfectly with the rising popularity of plant-based diets and veganism, where walnuts serve as a versatile, protein-rich alternative for meat and dairy products, driving consistent demand from food manufacturers. Furthermore, the snack industry is witnessing an exponential growth in demand for convenient, healthy, and natural ingredients, positioning walnut pieces as a premium addition to trail mixes, energy bars, and roasted nut blends. The baking and confectionery sectors remain cornerstone applications, utilizing walnut pieces extensively in breads, cakes, pastries, cookies, chocolates, and ice creams, where their unique texture and flavor profiles are highly valued. Beyond traditional uses, the functional food and nutraceutical industries are exploring walnuts for their potential in cognitive health, cardiovascular wellness, and anti-inflammatory properties, leading to their inclusion in specialized dietary supplements and fortified foods. Geographic shifts in supply and demand, influenced by climate change, geopolitical factors, and agricultural policies, are also shaping market dynamics, with key producing regions like California, Chile, and China (particularly Xinjiang province) playing pivotal roles in meeting global requirements. The demand for traceable, sustainably sourced, and organically certified walnut pieces is on an upward trajectory, reflecting a broader industry commitment to ethical and environmentally responsible practices. Technological advancements in harvesting, processing, and sorting, including optical sorting and advanced cracking machinery, are enhancing efficiency, reducing waste, and improving the overall quality and consistency of bulk walnut pieces, thereby impacting market pricing and competitiveness. The rise of e-commerce platforms and sophisticated global logistics networks has streamlined the procurement process for B2B buyers, allowing for more direct sourcing and specialized product requests. However, challenges persist, including price volatility influenced by harvest yields, pest control issues, water availability, and stringent international food safety regulations that necessitate robust quality control measures throughout the supply chain. Companies like Luhuawalnut, specializing in Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ, are strategically positioned to address these demands by focusing on high-quality, regionally distinct produce processed under rigorous standards. Their ability to deliver consistent quality and quantity in bulk formats is critical for large-scale industrial buyers. Understanding these multifaceted trends is crucial for any business operating within or looking to enter the bulk walnut market, ensuring strategic planning and adaptation to remain competitive and meet the evolving needs of a health-conscious global consumer base.

The Advanced Manufacturing Process of Bulk Walnut Pieces

The production of high-quality walnut pieces bulk involves a meticulously controlled, multi-stage manufacturing process designed to preserve the walnuts' nutritional integrity, flavor, and shelf life, while meeting stringent food safety standards. This journey begins with the careful harvesting of mature walnuts, typically from late summer to early autumn, ensuring optimal ripeness and quality. After mechanical or manual shaking of the trees, the fallen walnuts are collected and transported to initial processing facilities. The first critical step is hulling, where the green outer husk is removed, often using mechanical hullers that gently agitate the walnuts to separate them from the husk without damaging the shell. Following hulling, the walnuts undergo a thorough cleaning process to remove any residual debris, dirt, or foreign matter. This often involves washing and then drying. Proper drying is paramount, as it reduces the moisture content to a safe level (typically below 6-8%), preventing mold growth and preserving the kernel's quality during storage. This is frequently achieved using large-scale forced-air dryers, ensuring uniform moisture reduction. Once dried, the walnuts are ready for cracking. Advanced industrial cracking machines utilize precise pressure and impact mechanisms to crack the hard shells while minimizing damage to the delicate kernels inside. This stage is crucial for maximizing yield of intact halves and quarters. Post-cracking, an intricate shell-kernel separation process takes place. This typically involves a combination of air classification (using air currents to separate lighter shell fragments from heavier kernels), vibrating screens that sort by size, and gravity tables that further separate based on density. Even with advanced machinery, manual sorting and inspection remain vital, as human eyes are adept at identifying and removing any remaining shell pieces, foreign materials, or discolored/damaged kernels. This labor-intensive step is key to ensuring the purity and visual appeal of the final product. The sorted kernels are then categorized by size and type, such as halves, quarters, or smaller pieces, using a series of specialized screens and optical sorters. Optical sorters, leveraging advanced camera technology, can identify and remove kernels based on color, shape, and defects, ensuring consistency in batches. For a product like Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ, particular emphasis is placed on ensuring a high percentage of intact quarter pieces. Throughout this entire process, adherence to rigorous inspection standards like ISO 22000 (Food Safety Management System), HACCP (Hazard Analysis and Critical Control Points), and relevant national food safety regulations (e.g., FDA standards for imports) is non-negotiable. Regular testing for microbial contamination (e.g., E. coli, Salmonella), aflatoxins, moisture content, peroxide value (an indicator of rancidity), and foreign matter is conducted at various stages. The shelf life of walnut kernels is significantly influenced by proper handling and storage; typically, they have a shelf life of 12-24 months when stored in cool, dry conditions or refrigerated/frozen. This meticulous process ensures that the finished walnut pieces bulk are of premium quality, safe for consumption, and ready for use in diverse industries such as baking, confectionery, snack foods, dairy, and health supplements, where consistency and purity are paramount for product integrity and consumer safety.

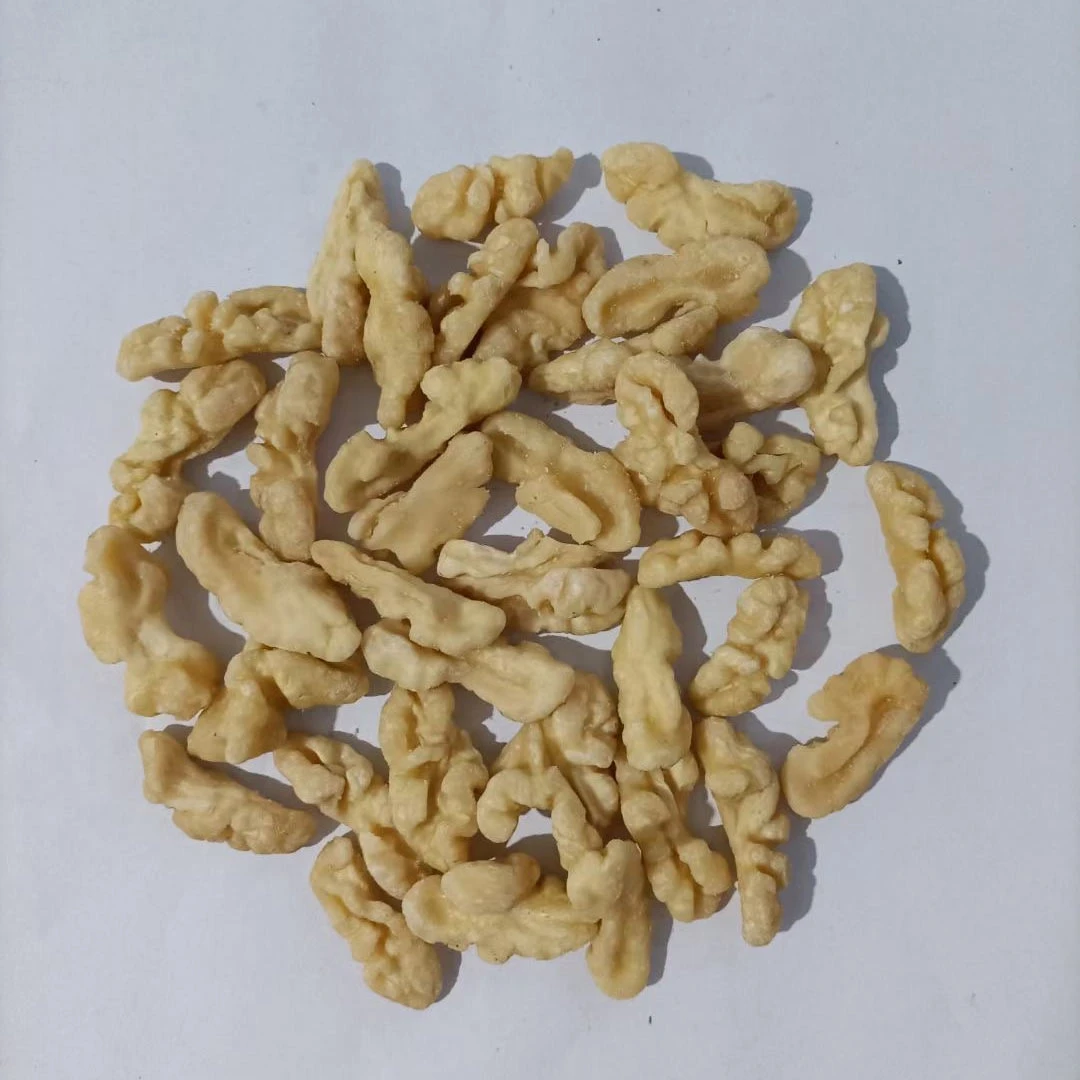

Image: Overview of the intricate processing steps for creating high-quality walnut pieces bulk.

Technical Parameters and Quality Specifications for Walnut Kernels

Understanding the precise technical parameters and quality specifications is paramount for B2B buyers seeking walnut pieces bulk, as these metrics directly impact the suitability for specific applications, product quality, and shelf stability. For products like Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ, several key attributes are meticulously controlled. Color is a primary visual indicator, typically categorized from "extra light" to "light amber" or "amber," with lighter colors generally commanding a premium due to their aesthetic appeal and perceived freshness, especially for snack applications or as toppings. Moisture content is critical, ideally maintained between 4.0% and 6.0% to inhibit microbial growth and prevent rancidity, which is a major concern for the longevity of the product. Higher moisture levels can lead to mold and bacterial spoilage, while excessively low levels can make the kernels brittle. Foreign matter, including shell fragments, dust, and other extraneous materials, must be virtually non-existent, with industry standards often setting limits below 0.01% to ensure product purity and consumer safety. Broken pieces and defects, such as shriveled kernels, insect damage, or discoloration, are carefully managed; for "quarter" specific products, the percentage of smaller pieces or halves should be minimal, often less than 5-10%. The sensory profile is also vital: high-quality walnuts should exhibit a characteristic fresh, nutty flavor with no off-notes, bitterness, or rancidity, which are often indicators of improper storage or oxidation. Nutritional parameters, while inherent to walnuts, are also monitored. For instance, the oil content, typically ranging from 60-70%, impacts texture and flavor, while the specific fatty acid profile, notably the high Alpha-Linolenic Acid (ALA) content (a type of Omega-3 fatty acid), is a key selling point for health-conscious consumers. Protein content is generally around 14-16%. Furthermore, microbiological specifications are stringent, with limits for total plate count, yeast and mold, coliforms, E. coli, and absence of Salmonella. Aflatoxin levels must be below international regulatory limits (e.g., EU limits of 2-4 µg/kg for total aflatoxins, depending on the specific type), which is a critical food safety concern requiring sophisticated testing protocols. Peroxide Value (PV) and Free Fatty Acids (FFA) are chemical indicators of oxidation and fat degradation, with lower values indicating fresher product and longer shelf life. For example, a PV typically below 5 meq O2/kg and FFA below 1% are desirable. These rigorous quality control measures, including pre-shipment inspections and third-party lab testing, assure buyers of consistent product integrity and compliance with international food safety and quality benchmarks. Buyers should request detailed Certificates of Analysis (CoA) for each batch to verify these parameters.

Image: Rigorous quality control measures ensuring purity and consistency in walnut pieces bulk.

Typical Specifications for Premium Bulk Walnut Kernels

| Parameter | Specification Range (Typical) | Impact on Application |

|---|---|---|

| Kernel Type | Quarter Walnut Kernel (LQ) | Ideal for baking, confectionery, and snack mixes requiring consistent sizing. |

| Color | Light / Light Amber | Visual appeal in final products; freshness indicator. Lighter colors preferred for toppings. |

| Moisture Content | 4.0% - 6.0% | Crucial for shelf stability; prevents mold and bacterial growth, maintains texture. |

| Foreign Matter | < 0.01% | Ensures purity and food safety, prevents equipment damage. |

| Shell Content | < 0.005% | Critical for safety and mouthfeel; indicates effective processing. |

| Broken/Defective Kernels | < 5% (of specified kernel type) | Impacts visual consistency and yield for manufacturers. |

| Peroxide Value (PV) | < 5 meq O2/kg | Indicates freshness and oxidation level; lower PV ensures longer shelf life and prevents rancidity. |

| Free Fatty Acids (FFA) | < 1% | Measure of fat degradation; lower FFA indicates higher quality and stability. |

| Aflatoxin | < 2-4 µg/kg (EU/US Compliant) | Critical food safety parameter; stringent testing required. |

| Microbiologicals (Total Plate Count) | < 10^5 CFU/g | General indicator of hygienic processing. |

| Storage | Cool, dry place (<10°C, RH <60%) | Optimizes shelf life and maintains sensory quality. |

Note: Specifications may vary slightly based on specific grade and customer requirements. Always refer to the product's Certificate of Analysis.

Versatile Application Scenarios for Bulk Walnut Pieces

The adaptability and rich nutritional profile of walnut pieces bulk make them an indispensable ingredient across a myriad of industrial applications, catering to diverse consumer needs and culinary preferences. One of the most significant sectors is the baking industry, where walnut pieces are widely used in a vast array of products, including artisan breads (like walnut-cranberry sourdough), muffins, cakes (carrot cake, banana bread), cookies, brownies, and pastries. Their distinct nutty flavor and satisfying crunch enhance the texture and taste of baked goods, providing an excellent mouthfeel. The confectionery industry also heavily relies on walnut pieces for chocolates, pralines, nougats, and various candy bars, offering both textural contrast and a rich, earthy flavor that complements sweet formulations. Many premium chocolate brands incorporate walnut kernels to add sophistication and depth to their products. In the rapidly expanding snack food market, bulk walnut pieces are a staple. They are a primary component in trail mixes, granola, snack bars, and roasted nut blends, appealing to health-conscious consumers looking for convenient, nutrient-dense options. The natural goodness of walnuts, combined with their portability, makes them ideal for on-the-go snacking solutions. The dairy and alternative dairy sectors are increasingly integrating walnuts into new product lines. This includes walnut-based milk and creamers, yogurts, and ice creams, offering plant-based alternatives that cater to lactose-intolerant or vegan consumers. Their creamy texture when processed into milk and their ability to impart a rich flavor profile are highly valued. Furthermore, the culinary world, particularly professional kitchens and food service providers, uses walnut pieces extensively in savory dishes. They are a popular addition to salads, often candied or roasted, providing crunch and flavor. Walnut pieces are also used in pesto sauces, stuffings for poultry or vegetables, and even as a component in vegetarian or vegan burger patties, demonstrating their versatility beyond sweet applications. For example, a renowned plant-based food manufacturer successfully integrated our Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ into their new line of savory vegan meat alternatives, praising the consistent sizing and fresh taste that contributed significantly to the product's texture and flavor complexity. The growing demand for health-oriented ingredients has also propelled walnut pieces into the nutraceutical and functional food industries, where they are incorporated into nutritional supplements, protein powders, and wellness bars, leveraging their known benefits for brain health and heart health due to their high Omega-3 content and antioxidants. This broad spectrum of applications underscores the commercial importance of sourcing high-quality, consistently graded walnut kernels 1kg and larger bulk formats, making them a cornerstone ingredient for manufacturers aiming to develop innovative, healthy, and appealing products for the global market.

Technical Advantages of Xinjiang 185 Walnut Kernels and Beyond

The selection of the right variety of walnut and its origin plays a crucial role in the overall quality and suitability for specific applications, and Xinjiang 185 Walnut Kernels stand out with distinct technical advantages that make them a preferred choice for walnut pieces bulk. The Xinjiang region of China is renowned for its ideal climate and fertile soil, fostering walnuts with superior characteristics. The "185" variety is particularly celebrated for its high kernel yield, meaning a greater proportion of the walnut is edible kernel compared to shell, translating to better economic efficiency for bulk buyers. These kernels are typically characterized by their light color, which is highly desirable for aesthetic appeal in finished food products, ensuring a premium look in baked goods, snack mixes, and confectionery. Furthermore, Xinjiang 185 walnuts possess a remarkably high oil content, often exceeding 65%, which contributes significantly to their rich, buttery flavor profile and creamy texture. This high oil content also means a denser, more satisfying mouthfeel, and when processed, it can enhance the moisture and shelf life of products like cakes and breads. Another notable advantage is their distinctively mild and sweet flavor, with less bitterness compared to some other walnut varieties. This nuanced flavor makes them exceptionally versatile, as they do not overpower other ingredients but rather complement them, allowing for broader application across various recipes. For manufacturers, consistency in quality and sizing is paramount, and the Xinjiang 185 variety, especially when processed into quarter pieces, offers remarkable uniformity. This consistent sizing (as found in Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ) reduces waste during processing and ensures a predictable output for industrial applications, which is critical for maintaining product integrity and operational efficiency. The robust shell structure of the "185" variety, while challenging for some cracking methods, allows for efficient cracking into larger, less broken pieces when using specialized machinery, further contributing to the high yield of desirable kernel sizes. Beyond the specific varietal advantages, a reliable supplier provides several technical and operational benefits. This includes state-of-the-art processing facilities equipped with advanced cracking, sorting, and quality control technologies like optical sorters and metal detectors, ensuring minimal foreign matter and adherence to strict specifications. Moreover, adherence to international food safety certifications such as ISO 22000, HACCP, and often BRC Global Standards signifies a commitment to the highest levels of hygiene, traceability, and quality assurance. Robust supply chain management, including optimal cold storage and efficient logistics for bulk shipments, minimizes degradation and extends the shelf life of the walnut kernels upon arrival. The ability to offer tailored packaging solutions, such as vacuum-sealed bags or nitrogen-flushed bulk container111s, further enhances preservation and extends freshness. These combined technical advantages, from the inherent qualities of the Xinjiang 185 variety to the sophisticated processing and supply chain expertise, translate into a superior bulk product that offers excellent performance, consistency, and value for B2B buyers across diverse food industries.

Navigating Supplier Selection: A Comparison for Bulk Walnut Purchases

Selecting the optimal supplier for walnut pieces bulk is a strategic decision for B2B buyers, impacting not only product quality and cost but also supply chain reliability and long-term business continuity. A comprehensive comparison among potential manufacturers or distributors is essential, focusing on several critical criteria beyond just price. Firstly, product quality and consistency are paramount. While many suppliers offer unshelled walnuts for sale or kernels, the ability to consistently deliver batches that meet precise specifications—such as color grade (e.g., Light Halves, Light Quarters), moisture content, foreign matter limits, and specific kernel sizes (e.g., Quarter Walnut Kernel LQ for baking)—is a key differentiator. Reputable suppliers will provide detailed Certificates of Analysis (CoA) for each shipment, verifying these parameters, and will also have a history of passing third-party audits. Secondly, certifications and compliance are non-negotiable. Manufacturers adhering to globally recognized food safety standards like ISO 22000, HACCP, FSSC 22000, and BRC Global Standards demonstrate a robust commitment to food safety management and quality assurance. Organic certifications (e.g., USDA Organic, EU Organic) or specific country-of-origin certifications further assure buyers of specific sourcing and processing practices. Third, processing capabilities and technology are crucial. Modern suppliers utilize advanced machinery for cracking, sorting (including optical sorters for color and defect removal), and packaging to maximize kernel integrity and minimize shell content and breakage. Their ability to handle large volumes efficiently while maintaining quality speaks to their operational maturity. Fourth, supply chain transparency and traceability are increasingly important. A reliable supplier should offer end-to-end traceability, from farm to packaging, providing clarity on the origin of the walnuts, harvest dates, and processing steps. This is vital for managing recalls, ensuring ethical sourcing, and meeting consumer demand for transparency. Fifth, logistical capabilities and packaging solutions are practical considerations. Suppliers must be able to manage international shipping efficiently, offering appropriate packaging (e.g., vacuum-sealed cartons, nitrogen-flushed bags, bulk totes) that preserves freshness and extends shelf life during transit and storage. Their ability to meet specific delivery schedules and handle customs procedures smoothly can significantly reduce operational headaches for buyers. Finally, customer service and customization options reflect a supplier's commitment to partnership. This includes responsiveness to inquiries, willingness to provide samples, flexibility in meeting specific product requirements (e.g., specific sizing, roasting, or packaging), and robust after-sales support. For instance, Luhuawalnut, specializing in Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ, distinguishes itself through its direct sourcing from prime Xinjiang orchards, ensuring varietal authenticity and quality, combined with advanced processing and adherence to international food safety standards, offering a compelling proposition for discerning industrial buyers prioritizing quality, consistency, and reliable supply. A comprehensive vendor assessment that weighs these factors against competitive pricing will lead to a more sustainable and mutually beneficial sourcing relationship.

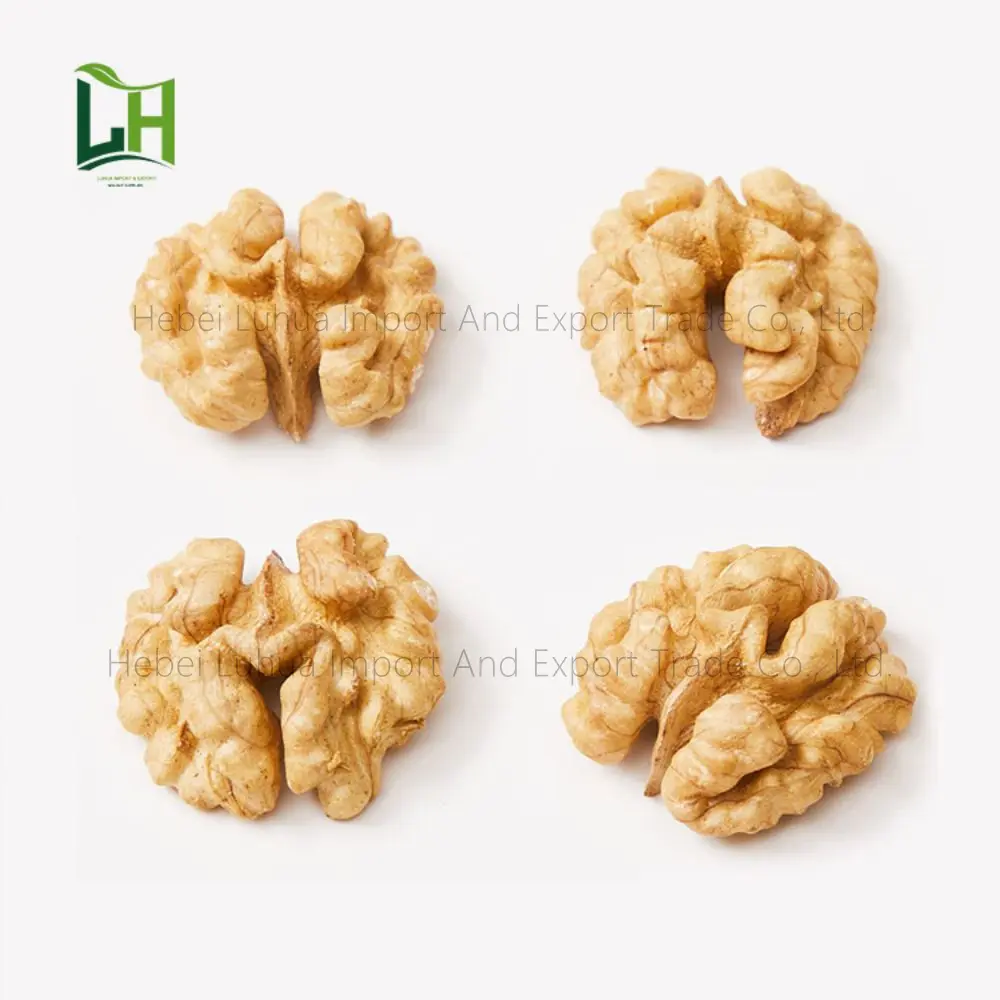

Image: A closer look at quality inspection for unshelled walnuts prior to processing.

Supplier Comparison Checklist for Bulk Walnut Kernels

| Criterion | Leading Supplier (e.g., Luhuawalnut) | Typical Competitor | Buyer Impact |

|---|---|---|---|

| Product Origin & Variety | Xinjiang 185 (Superior Flavor, High Yield) | Mixed origins, standard varieties | Consistency in taste, texture, and nutritional profile. |

| Quality Certifications | ISO 22000, HACCP, FDA Registered, (Potential Organic) | Basic food safety only, fewer international certs | Ensures compliance, reduces risk, builds trust. |

| Processing Technology | Advanced Optical Sorting, Automated Cracking, Integrated QC | Standard mechanical sorting, more manual checks | Purity (low foreign matter), consistent sizing, reduced defects. |

| Product Consistency | Very High (Precise Moisture, Color, Breakage Rates) | Moderate, batch-to-batch variation possible | Predictable performance in manufacturing, less waste. |

| Supply Chain Traceability | Full farm-to-packaging traceability | Limited or partial traceability | Risk management, ethical sourcing verification. |

| Packaging Solutions | Vacuum-sealed, Nitrogen-flushed options, various bulk sizes | Standard bulk bags only | Extended shelf life, maintained freshness, tailored for logistics. |

| Customer Support & Customization | Dedicated Account Manager, Custom Grades/Packaging | Standard product offerings, limited support | Responsive service, solutions tailored to specific needs. |

This table provides a generalized comparison. Buyers should conduct thorough due diligence.

Tailored Solutions and Customization for Bulk Walnut Needs

In the highly specialized B2B food industry, a "one-size-fits-all" approach rarely suffices for critical ingredients like walnut pieces bulk. Manufacturers, bakeries, and snack companies often have unique requirements concerning product specifications, packaging, and logistical considerations. Recognizing this, leading suppliers offer comprehensive customization and tailored solutions to meet these distinct needs, thereby becoming true partners rather than mere vendors. One primary area of customization lies in product specifications. While standard grades like "Light Quarters" or "Light Amber Pieces" are common, a buyer might require a specific moisture content range for a unique drying process, or an even tighter tolerance on foreign matter, perhaps for automated lines sensitive to minute debris. Suppliers can work to select specific batches or employ additional sorting processes to meet these ultra-specific quality parameters. For instance, a confectionery company might need walnuts with a very specific fat content to ensure optimal binding in chocolate bars, or a bakery might demand a particular size distribution of walnut kernels for uniform dispersion in their bread dough. Packaging solutions are another significant area for customization. While standard bulk bags (e.g., 25kg or 1000kg tote bags) are prevalent, a supplier can offer vacuum-sealed bags to extend shelf life for long-distance transport or storage in challenging climates, or even nitrogen-flushed packaging to prevent oxidation for highly sensitive applications. Smaller custom carton sizes might be available for clients with limited storage space or specific production batch sizes. Private labeling is also a common request, where the supplier packages the walnuts under the buyer's brand, maintaining anonymity of the source while benefiting from the supplier's processing expertise. Furthermore, logistics and delivery schedules can be customized. A large-scale manufacturer might require just-in-time (JIT) delivery to minimize inventory holding costs, necessitating precise scheduling and reliable transportation. Conversely, a client in a remote location might need consolidated shipments or specific freight forwarding arrangements. A proactive supplier will engage in detailed discussions to understand the client's production cycles, storage capabilities, and regional distribution network to optimize delivery. Consider an example where a major international cereal manufacturer required walnut kernels 1kg portions to be integrated into their automated mixing lines but with a stringent specification for color consistency and minimal breakage. Our team at Luhuawalnut collaborated closely with their R&D department, conducting trials with specific "Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ" batches, refining the optical sorting parameters, and developing a custom packaging solution that ensured product integrity from our facility to their production line. This level of collaborative problem-solving and adaptable service exemplifies the value of a supplier capable of offering truly bespoke solutions, transcending transactional exchanges to build enduring, strategic partnerships that enhance efficiency, product quality, and competitive advantage for the B2B buyer.

Case Studies: Successful Integrations of Bulk Walnut Pieces

Real-world application cases demonstrate the tangible benefits and versatility of high-quality walnut pieces bulk in diverse industrial settings, showcasing how a reliable supply chain and superior product can significantly enhance manufacturing processes and final product appeal. These examples highlight the direct impact of selecting a partner committed to excellence in bulk ingredients. Consider a leading European bakery chain specializing in artisan breads and pastries. This client previously struggled with inconsistent sizing and varying moisture levels from their former walnut supplier, which led to operational inefficiencies, increased waste, and undesirable texture variations in their flagship walnut bread. Upon switching to our Xinjiang 185 Walnut Kernel Quarter Walnut Kernel LQ, they observed a dramatic improvement. The consistent "quarter" sizing ensured uniform distribution throughout the dough, preventing clumps or sparse areas, while the optimal moisture content maintained the desired crumb structure and extended the freshness of their baked goods. The bakery reported a 15% reduction in production waste related to inconsistent ingredient quality and a noticeable increase in positive customer feedback regarding product consistency and richness of flavor. This case illustrates how precision in sizing and moisture control for walnut kernels directly translates to enhanced product quality and cost savings for the industrial baker. Another compelling case involves a rapidly growing North American snack food manufacturer focused on premium trail mixes and health bars. Their previous supplier of walnut pieces bulk often delivered product with higher-than-acceptable levels of shell fragments and discolored pieces, which necessitated costly manual sorting at their facility and, on occasion, resulted in customer complaints. After partnering with Luhuawalnut, leveraging our advanced optical sorting technology and stringent quality control protocols, the manufacturer received exceptionally clean and uniformly colored walnut pieces. This minimized their internal sorting labor by 80%, allowing them to reallocate resources to innovation and expansion. The improved purity and visual appeal of the walnuts also enhanced the overall premium perception of their snack mixes, contributing to a 10% increase in market share within their segment. This exemplifies how superior processing and impurity reduction contribute directly to operational efficiency and brand reputation. A final example highlights a prominent organic food brand expanding its line of plant-based protein meals. They required organic unshelled walnuts for sale, but processed into very specific fine pieces for use as a meat alternative base. We provided them with certified organic Xinjiang 185 walnut pieces, custom-milled to their desired particle size, while maintaining the walnuts' nutritional integrity and fresh flavor. This customized solution enabled the brand to launch a successful new product line that met stringent organic standards and resonated strongly with their target health-conscious consumers. These diverse application cases underscore the critical role of a specialized and responsive bulk walnut supplier in empowering B2B clients to achieve their production goals, innovate new products, and ultimately succeed in competitive markets by ensuring the highest quality of their core ingredients.

Image: Packaging solutions for bulk walnut kernels, ensuring freshness and optimal transport.

Ensuring Trustworthiness: FAQs, Delivery, and Warranty Commitments

Establishing trust and transparency is foundational in the B2B supply chain, particularly when dealing with high-volume, perishable goods like walnut pieces bulk. Professional suppliers prioritize comprehensive support, clear communication, and robust guarantees to assure buyers of reliability and product integrity. To address common concerns, a detailed Frequently Asked Questions (FAQ) module is invaluable. Typical questions might include: "What is the minimum order quantity for walnut kernels?", "Can I request samples before placing a bulk order?", "What are your lead times for international shipments?", "Do you offer different grades or specific cuts of walnut pieces?", "What certifications do your products hold?", and "How should the walnuts be stored upon arrival to maximize shelf life?". Clear, concise answers to these questions pre-empt concerns and streamline the ordering process. For instance, Luhuawalnut typically offers flexible MOQs starting from 20-foot container111 loads for bulk shipments, with smaller sample orders available upon request to facilitate quality assessment prior to commitment. Delivery and logistics are critical components of trustworthiness. Suppliers should provide transparent information regarding their delivery capabilities, including estimated transit times for various regions, available shipping methods (sea freight, air freight), and incoterms (e.g., FOB, CIF, DDP). They should also clearly outline their processes for customs clearance and documentation, ensuring a smooth and compliant import experience for international buyers. For example, our logistics team provides real-time tracking updates and manages all necessary export/import documentation, simplifying the supply chain for our global partners. Packaging types, such as vacuum-sealed bags or nitrogen-flushed bulk container111s, and their respective impacts on product preservation during transit, should also be communicated. Furthermore, a strong warranty and quality assurance commitment underpins trust. This includes a clear policy on product quality guarantees, outlining procedures for addressing non-conformance issues, damages during transit, or any deviations from agreed-upon specifications. A reputable supplier will have a well-defined complaint resolution process, often involving independent third-party lab testing for disputed claims, and a commitment to prompt investigation and remediation, which might include replacement shipments or credit notes. Our commitment includes a guarantee against defects in material and processing, backed by our ISO 22000 certified quality management system, ensuring that any issue will be addressed with urgency and fairness. Finally, accessible customer support is vital. This means having dedicated account managers or customer service representatives who can provide personalized assistance, respond promptly to inquiries, and offer technical advice or support throughout the procurement lifecycle. Such comprehensive support, coupled with transparent policies on delivery and quality, builds enduring trust and reinforces the supplier's position as a reliable and responsible partner in the B2B food ingredient sector.

Further Research and Industry Insights

For B2B professionals and technical decision-makers seeking to deepen their understanding of the global walnut market and the specific dynamics of walnut pieces bulk, engaging with authoritative industry reports and academic research is indispensable. The insights derived from these sources provide a macro-level perspective on market forecasts, consumer trends, and technological advancements that shape the supply chain. For instance, comprehensive market analysis reports from organizations like Grand View Research or Mordor Intelligence offer detailed segmentation by application, product type, and geography, often including competitive landscape analysis and projected growth rates for the global tree nuts market, specifically highlighting the trajectory for walnuts. These reports frequently delve into the impact of health and wellness trends, the rise of plant-based diets, and the increasing demand for organic and sustainably sourced ingredients on the walnut sector. Furthermore, agricultural statistics from governmental bodies such as the USDA Foreign Agricultural Service or the Food and Agriculture Organization (FAO) of the United Nations provide crucial data on global walnut production, trade volumes, and pricing trends, allowing buyers to anticipate market fluctuations and plan their procurement strategies more effectively. These resources are critical for understanding the availability of unshelled walnuts for sale and processed kernel forms like walnut kernels 1kg in different regions. Academic journals focused on food science, agricultural economics, and nutrition also publish peer-reviewed studies that offer in-depth insights into the post-harvest physiology of walnuts, optimal storage conditions to prevent rancidity, advanced processing techniques for quality retention, and the bioactive compounds that contribute to their health benefits. For example, research on the oxidative stability of walnut lipids or the efficacy of various packaging methods in preserving freshness can directly inform procurement and storage decisions for bulk quantities. Industry-specific forums and trade associations, such as the International Nut & Dried Fruit Council (INC), serve as valuable platforms for networking, accessing proprietary market intelligence, and staying abreast of regulatory changes and best practices within the nut industry. Their annual conferences and publications often feature discussions on challenges like pest management, water conservation in walnut cultivation, and innovations in processing technology. Staying informed through these diverse, authoritative channels ensures that B2B buyers and strategists are equipped with the most current and robust data to make informed decisions regarding sourcing, quality control, and strategic partnerships in the dynamic global market for bulk walnut ingredients. Continued engagement with these resources fosters an informed and proactive approach to managing complex supply chains and maintaining a competitive edge.

Key Industry Resources & Citations:

- Grand View Research. (2023). Walnut Market Size, Share & Trends Analysis Report. Retrieved from: https://www.grandviewresearch.com/industry-analysis/walnut-market

- Mordor Intelligence. (2023). Walnuts Market Size & Share Analysis - Growth Trends & Forecasts. Retrieved from: https://www.mordorintelligence.com/industry-reports/walnut-market

- International Nut & Dried Fruit Council (INC). (Ongoing Publications and Statistics). Retrieved from: https://www.nutfruit.org/

- USDA Foreign Agricultural Service. (Various Reports on Tree Nuts). Retrieved from: https://www.fas.usda.gov/ (Search for 'Tree Nuts' or 'Walnuts')

- Food and Agriculture Organization of the United Nations (FAO). (FAOSTAT data on Nuts and Fruits). Retrieved from: https://www.fao.org/faostat/en/#data

Post time:Aug . 10, 2025 09:20