Market Dynamics and Strategic Importance of Walnut Kernels

The global market for walnuts, particularly shelled walnuts, is experiencing robust growth driven by increasing consumer awareness of their nutritional benefits and versatility across various culinary applications. Industry reports project a significant CAGR for walnut products, fueled by rising demand in food processing, confectionery, bakery, and health supplement sectors. Unlike unshelled walnuts, shelled variants offer unparalleled convenience, reducing preparation time and waste for industrial users and consumers alike. This shift underscores a broader trend towards value-added, ready-to-use ingredients in the B2B supply chain, emphasizing efficiency and consistent quality. The strategic importance of sourcing high-quality Yunnan Walnut Kernels Extra Light Halves (ELH) and Light Halves (LH) cannot be overstated, as they represent a premium segment in this evolving market, meeting stringent requirements for appearance, taste, and nutritional profile.

The demand for precise specifications, such as a walnut 1 kg without shell, is increasingly common in large-scale industrial applications where portion control and consistent yield are critical. This precision minimizes operational losses and optimizes production processes. Emerging markets, alongside established ones, are showing a strong preference for kernels that adhere to international quality and safety standards, making compliance a key differentiator. Furthermore, sustainability and ethical sourcing practices are gaining prominence, influencing procurement decisions and fostering long-term partnerships between suppliers and buyers.

The Advanced Production Process of Shelled Walnuts

The manufacturing process for high-quality shelled walnuts, particularly the Yunnan Walnut Kernels Extra Light Halves (ELH) and Light Halves (LH), is a sophisticated multi-stage operation designed to preserve their natural integrity and nutritional value. The journey begins with the careful selection of premium unshelled walnuts, typically harvested at optimal maturity to ensure superior flavor and texture. These raw materials undergo an initial sorting phase to remove debris and substandard nuts.

The core of the process involves precision cracking, often utilizing specialized machinery that minimizes kernel damage while efficiently separating the shell. This is a critical step, as crude methods can lead to excessive breakage, diminishing the yield of valuable halves and pieces. Following cracking, advanced optical sorting machines are employed. These machines leverage sophisticated imaging technology to identify and segregate kernels based on color, size, and the presence of foreign material or shell fragments. This ensures that only the purest, most visually appealing kernels proceed to the next stage. Manual inspection teams complement this automated process, performing meticulous checks to catch any imperfections missed by the machinery, guaranteeing adherence to stringent quality parameters like those stipulated by ISO 22000 and HACCP food safety management systems.

Post-sorting, the kernels undergo controlled drying to achieve the optimal moisture content, typically between 4% and 6%. This step is vital for extending shelf life, preventing mold growth, and maintaining the characteristic crispness and flavor. Packaging occurs in specialized facilities under hygienic conditions, often using vacuum sealing or modified atmosphere packaging to protect the kernels from oxidation and contamination. This rigorous process ensures that products like the Yunnan Walnut Kernels ELH and LH not only meet but exceed international standards for food safety and quality, ensuring a consistent product for demanding industrial applications. The typical shelf life for properly stored shelled walnuts can exceed 12 months, depending on storage conditions and packaging.

Technical Parameters and Quality Specifications

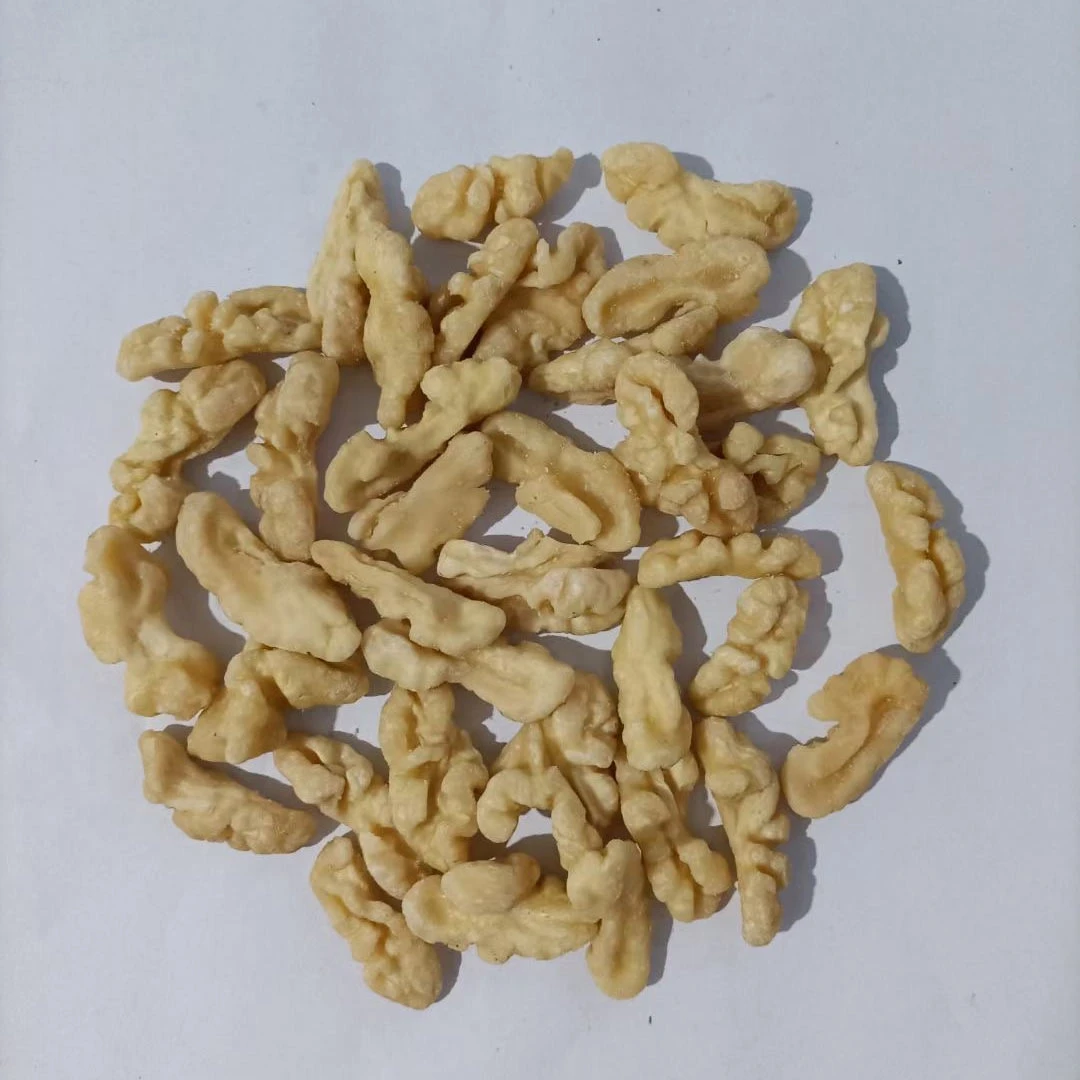

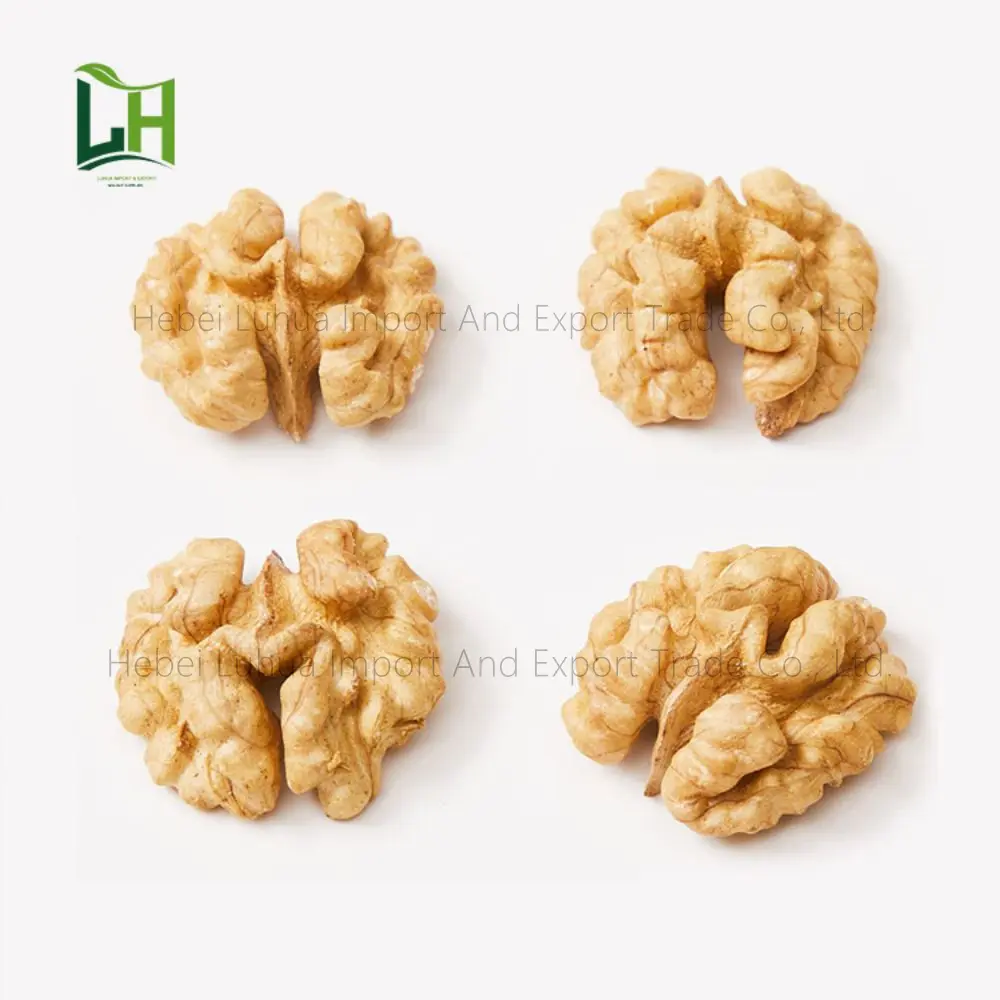

Precision in specification is paramount for B2B clients utilizing shelled walnuts as a core ingredient. Yunnan Walnut Kernels are categorized by size and color, which directly impacts their application and market value. "Extra Light Halves" (ELH) and "Light Halves" (LH) refer to the color grade, with ELH indicating a very pale, almost white color, and LH being slightly darker. These visual attributes are crucial for high-end confectionery and bakery products where aesthetics are as important as taste.

Below is a detailed table outlining typical specifications for premium shelled walnuts, demonstrating the rigorous quality control applied to products like Yunnan Walnut Kernels. These parameters ensure consistency and compliance with international food safety and quality standards, including FDA regulations for imported food products.

Yunnan Walnut Kernels: Technical Specifications

Applications and Technical Advantages

The versatility of premium shelled walnuts like Yunnan Walnut Kernels ELH and LH makes them indispensable across a wide spectrum of industries. In the bakery sector, their distinct flavor and texture enhance a variety of products from artisan breads and cakes to cookies and pastries. Confectionery manufacturers leverage their rich taste and aesthetic appeal in chocolates, pralines, and nut bars. The health food and snack industry benefits significantly from their high omega-3 fatty acid content, protein, and fiber, making them ideal for trail mixes, healthy snacks, and nutritional supplements.

From a technical perspective, the consistent sizing and low moisture content of our kernels contribute to superior product stability and extended shelf life in finished goods. For instance, in sensitive applications like premium ice creams or dairy alternatives, the stability of high-quality shelled walnuts prevents unwanted textural changes or flavor degradation. The minimal foreign matter and shell content significantly reduce processing time and costs for industrial users, eliminating the need for further sorting or cleaning steps. This translates into tangible operational efficiencies and reduced waste, directly impacting the bottom line for businesses requiring bulk walnut 1 kg without shell or larger quantities. Our products are also frequently specified for clean label initiatives due to their natural processing and lack of additives, appealing to the growing consumer demand for transparent and wholesome ingredients.

Custom Solutions and Manufacturer Comparison

Recognizing the diverse needs of B2B clients, we offer comprehensive custom solutions for shelled walnuts, including specific kernel sizes (halves, quarters, pieces), moisture levels, and packaging formats. Whether a client requires precise particle distribution for granola bars or specific color consistency for premium chocolate coatings, our technical team collaborates closely to develop tailored specifications that align with their production processes and final product requirements. Our flexibility extends to various packaging options, from vacuum-sealed bags of walnut 1 kg without shell for smaller scale operations to bulk industrial packaging.

When comparing manufacturers of shelled walnuts, several key differentiators emerge beyond just price. Factors such as a robust supply chain, transparent sourcing practices, adherence to international certifications (e.g., ISO, HACCP, BRCGS), consistency in product quality across batches, and responsive customer support are critical. Our long-standing relationships with growers in Yunnan, combined with our advanced processing capabilities, enable us to consistently deliver superior quality Yunnan Walnut Kernels. We differentiate ourselves through our unwavering commitment to quality assurance, backed by regular third-party audits and comprehensive traceability systems from farm to finished product. This dedication ensures reliable supply and mitigates risks associated with quality variations often found in less rigorously managed supply chains.

Case Studies and Client Success

Our Yunnan Walnut Kernels have been integral to the success of numerous clients across diverse industries. For instance, a major European confectionery brand transitioned from a fragmented supply chain to sourcing our ELH kernels exclusively for their premium chocolate bars. This shift resulted in a 15% reduction in production line rejections due to foreign matter, and a noticeable improvement in the sensory attributes of their final product, leading to positive consumer feedback and increased market share. The consistent color and size of our Extra Light Halves allowed them to maintain a uniform visual appeal across all batches, a critical factor for their brand identity.

In another instance, a leading North American health snack manufacturer sought a reliable source for shelled walnuts with guaranteed low microbial counts for their raw and minimally processed snack mixes. Our stringent quality control measures, including advanced microbial testing and cold storage capabilities, enabled us to consistently meet their exacting specifications. This partnership facilitated their expansion into new markets requiring certified organic and non-GMO ingredients, further demonstrating the adaptability and quality assurance embedded in our supply chain for shelled walnuts. These examples underscore our capability to not just supply, but to partner with clients in achieving their production and market objectives.

Quality Assurance, Trustworthiness, and Support

Our commitment to quality assurance for shelled walnuts is integral to our operations, encompassing every stage from cultivation oversight to final packaging. We adhere to stringent international food safety and quality management systems, including ISO 22000, HACCP, and are prepared to meet specific country import regulations such as FDA and EU standards. Our facilities undergo regular internal and external audits to ensure compliance and continuous improvement. We also provide comprehensive Certificates of Analysis (CoA) with every shipment, detailing key parameters like moisture content, foreign matter, color grade, and microbial load, providing complete transparency and traceability for every batch of walnut 1 kg without shell or larger orders.

FAQ

-

Q: What is your typical lead time for bulk orders?

A: Our standard delivery cycle ranges from 2-4 weeks post-order confirmation, depending on order size and destination. Expedited options are available for urgent requirements. -

Q: Do you offer samples for product evaluation?

A: Yes, we provide samples of our Yunnan Walnut Kernels ELH and LH for prospective B2B clients to evaluate quality and suitability for their applications. -

Q: What is your quality guarantee for shelled walnuts?

A: We offer a comprehensive quality guarantee, ensuring our products meet agreed-upon specifications and are free from defects. Any discrepancies are addressed promptly by our dedicated customer support team. Our commitment extends to providing consistent product quality for up to 12 months under recommended storage conditions.

Our responsive customer support team is available to assist with technical queries, order tracking, and any post-delivery concerns. We believe in building long-term partnerships based on trust and mutual success, ensuring that our Yunnan Walnut Kernels are not just a commodity, but a reliable, high-performing ingredient in your supply chain.

References

- Smith, J. et al. "Global Walnut Market Analysis and Forecasts." Journal of Agricultural Economics and Food Systems.

- Food and Agriculture Organization of the United Nations (FAO). "Nut Production Statistics and Market Trends." FAOSTAT Database.

- International Nut and Dried Fruit Council (INC). "Technical Specifications for Walnut Kernels." INC Publications.

- U.S. Food and Drug Administration (FDA). "Food Safety Modernization Act (FSMA) Compliance Guidelines." FDA Website.

- International Organization for Standardization (ISO). "ISO 22000 Food Safety Management Systems." ISO Standards Collection.

Post time:Aug . 12, 2025 05:40