Navigating the Global Market for Premium Shelled Walnuts

The global demand for high-quality shelled walnuts continues its upward trajectory, driven by increasing consumer awareness of their nutritional benefits and versatility across various food industries. Valued for their rich flavor, beneficial fats, and protein content, shelled walnuts are a staple in sectors ranging from artisanal baking and confectionery to health-conscious snack formulations and functional food products. Market research indicates a compound annual growth rate (CAGR) of over 5% for the global walnut market, with a significant portion attributed to processed kernels. This growth is fueled by rising disposable incomes, evolving dietary preferences, and the convenience offered by ready-to-use walnut kernels, bypassing the need for processing unshelled walnuts.

Industry trends highlight a strong preference for specific kernel grades, such as Extra Light Halves (ELH) and Light Halves (LH), which are prized for their consistent color, size, and minimal breakage, making them ideal for premium applications. As suppliers, understanding these nuances and ensuring stringent quality control measures are paramount. The focus is shifting towards sustainable sourcing and transparent supply chains, ensuring both product excellence and ethical practices. For industrial buyers seeking large quantities, such as walnut 1 kg without shell bulk options, consistent supply, competitive pricing, and adherence to international food safety standards are critical considerations in their procurement strategy.

The Advanced Processing Journey of Yunnan Walnut Kernels

Producing premium shelled walnuts involves a meticulous multi-stage process designed to preserve their natural quality and extend shelf life. Our Yunnan Walnut Kernels undergo a sophisticated journey from harvest to packaging. Initially, freshly harvested walnuts are carefully sorted to remove debris and damaged nuts. This initial sorting is crucial for maintaining the integrity of the batch. Following this, the walnuts are meticulously cleaned and dried to an optimal moisture content, typically between 4% and 6%, which is vital for preventing mold growth and preserving crispness. Proper drying is a critical step in ensuring the long-term stability and quality of the final product.

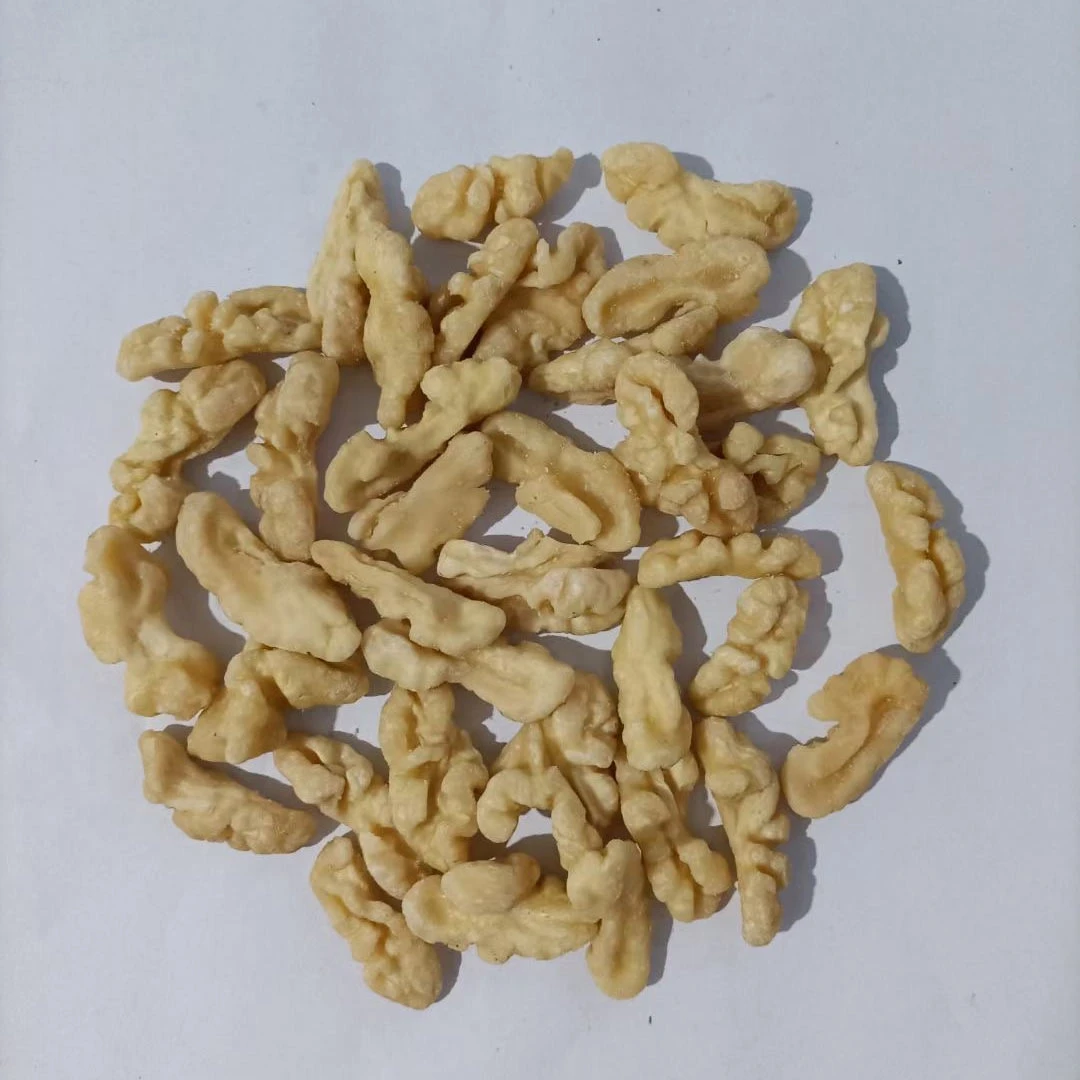

The next phase involves advanced mechanical cracking, where specialized machinery efficiently separates the kernel from the shell with minimal breakage. This process is calibrated to handle various sizes of unshelled walnuts, ensuring high yield of intact halves. Post-cracking, an intricate hand-sorting and optical sorting process occurs. Human sorters meticulously inspect each kernel for color, size, and imperfections, while advanced optical sorters use camera technology to detect and remove foreign materials or discolored pieces that might be missed by the human eye. This dual-layer inspection guarantees superior quality control, separating Extra Light Halves (ELH) and Light Halves (LH) based on strict color and integrity standards.

Before packaging, the kernels undergo a final quality check, including metal detection and microbiological testing, to ensure compliance with international food safety standards such as ISO 22000, HACCP, and BRC. The final product, whether a bulk order of walnut 1 kg without shell or larger industrial quantities, is then vacuum-sealed or nitrogen-flushed in specialized packaging to prevent oxidation and extend shelf life, which typically ranges from 12 to 24 months when stored correctly. This comprehensive process ensures that every batch of Yunnan Walnut Kernels meets the highest industry benchmarks for purity, safety, and sensory attributes.

The robust manufacturing process emphasizes material quality derived from premium Yunnan walnuts, known for their large kernel size and delicate flavor. Each step, from initial cleaning to final packaging, integrates stringent detection standards. For instance, moisture content is continually monitored using precise instruments, ensuring it remains within the optimal range of 4-6%. Peroxide value (PV) and Free Fatty Acids (FFA) are also routinely tested to guarantee freshness and prevent rancidity, with typical PV levels below 5 meq O2/kg and FFA below 1.5%. These parameters are critical for maintaining the walnuts' organoleptic properties and extending their usable life across diverse applications, from high-temperature baking to cold-pressed oil extraction.

Key Technical Parameters of Shelled Walnuts

Understanding the precise technical specifications of shelled walnuts is essential for industrial applications, ensuring consistency and compliance with product formulations. The following table outlines typical parameters for our Yunnan Walnut Kernels, applicable for Extra Light Halves (ELH) and Light Halves (LH), highlighting critical quality indicators that impact performance in various manufacturing processes. These metrics are consistently monitored and verified through laboratory testing for every batch.

| Parameter | Specification (ELH/LH) | Relevance to Application |

|---|---|---|

| Moisture Content | Max 6.0% (typically 4-5%) | Prevents mold, maintains crispness, extends shelf life. Critical for baking and snack industries. |

| Peroxide Value (PV) | Max 5.0 meq O2/kg | Indicates freshness; lower values mean less oxidation and rancidity. Essential for product flavor stability. |

| Free Fatty Acids (FFA) | Max 1.5% | Measures lipid hydrolysis; low FFA indicates good quality and proper storage. Impacts taste and shelf stability. |

| Total Fat | 65-70% | Key nutritional component; impacts texture and richness in finished products. |

| Protein | 14-16% | Significant protein source; enhances nutritional profile of health foods and snacks. |

| Foreign Matter | Max 0.01% | Ensures product purity and safety, critical for industrial processing lines. |

| Broken Pieces ( | ELH: Max 3%; LH: Max 5% | Affects visual appeal and mouthfeel; lower breakage is preferred for premium applications. |

Versatile Application Scenarios for Yunnan Walnut Kernels

The superior quality of Yunnan Walnut Kernels, including both Extra Light Halves (ELH) and Light Halves (LH), makes them exceptionally versatile for a wide array of industrial and commercial applications. Their consistent size, vibrant color, and fresh taste are highly valued across various sectors. In the baking industry, shelled walnuts are indispensable for creating premium breads, pastries, cakes, and cookies. Their distinctive crunch and rich flavor profile elevate gourmet baked goods, providing both texture and nutritional value. For instance, a leading bakery reported a 15% increase in customer satisfaction for their walnut-infused sourdough following the switch to high-grade Yunnan ELH kernels.

The confectionery sector extensively utilizes these kernels in chocolates, nougats, pralines, and other sweet treats. The aesthetic appeal of whole or half kernels as inclusions or toppings is critical, and our rigorous sorting process ensures minimal breakage, enhancing product presentation. In the rapidly expanding health and functional food market, shelled walnuts are key ingredients in trail mixes, granola bars, plant-based protein formulations, and nut butters due to their omega-3 fatty acids and antioxidant content. Food service establishments also benefit, incorporating them into salads, hot dishes, and specialty desserts, reducing prep time compared to using unshelled walnuts.

Beyond direct consumption, the kernels find applications in cold-pressed walnut oil production, where the high oil content and low FFA ensure superior oil quality. Their extensive shelf life and consistent quality mean they can be efficiently integrated into large-scale production lines, whether for a client needing walnut 1 kg without shell for a specialized product run or a major food manufacturer requiring tons for mass production. This adaptability underscores their value as a premium ingredient across diverse food processing industries globally.

Technical Advantages of Sourcing from LuHua Walnut

Choosing LuHua Walnut as your supplier for shelled walnuts offers distinct technical advantages that translate directly into operational efficiency and superior product quality for our B2B partners. Our primary advantage stems from vertically integrated operations, controlling the entire supply chain from cultivation in prime Yunnan regions to advanced processing and global distribution of our premium shelled walnuts. This ensures unparalleled traceability and consistent quality from farm to final delivery, a level of control few competitors can match.

Our state-of-the-art processing facilities utilize cutting-edge technology, including multi-stage optical sorters and advanced metal detection systems, to guarantee purity and minimize foreign materials. This precision technology significantly reduces the need for extensive incoming quality checks for our clients, saving time and resources. Furthermore, our focus on maintaining optimal moisture content (typically 4-5%) and low peroxide values directly contributes to an extended shelf life, reducing waste and allowing for greater flexibility in inventory management for bulk orders, such as walnut 1 kg without shell quantities or larger.

We specialize in providing high yields of Extra Light Halves (ELH) and Light Halves (LH), which are the most sought-after grades due to their aesthetic appeal and consistent sizing, making them ideal for high-end applications where visual uniformity is critical. Our commitment to strict adherence to international standards like ISO, HACCP, and BRC Global Standards provides an additional layer of assurance regarding product safety and compliance. This robust quality management system differentiates us and builds trust, allowing our clients to confidently integrate our products into their most demanding applications.

Comparing Yunnan Walnut Kernels: ELH vs. LH Grades

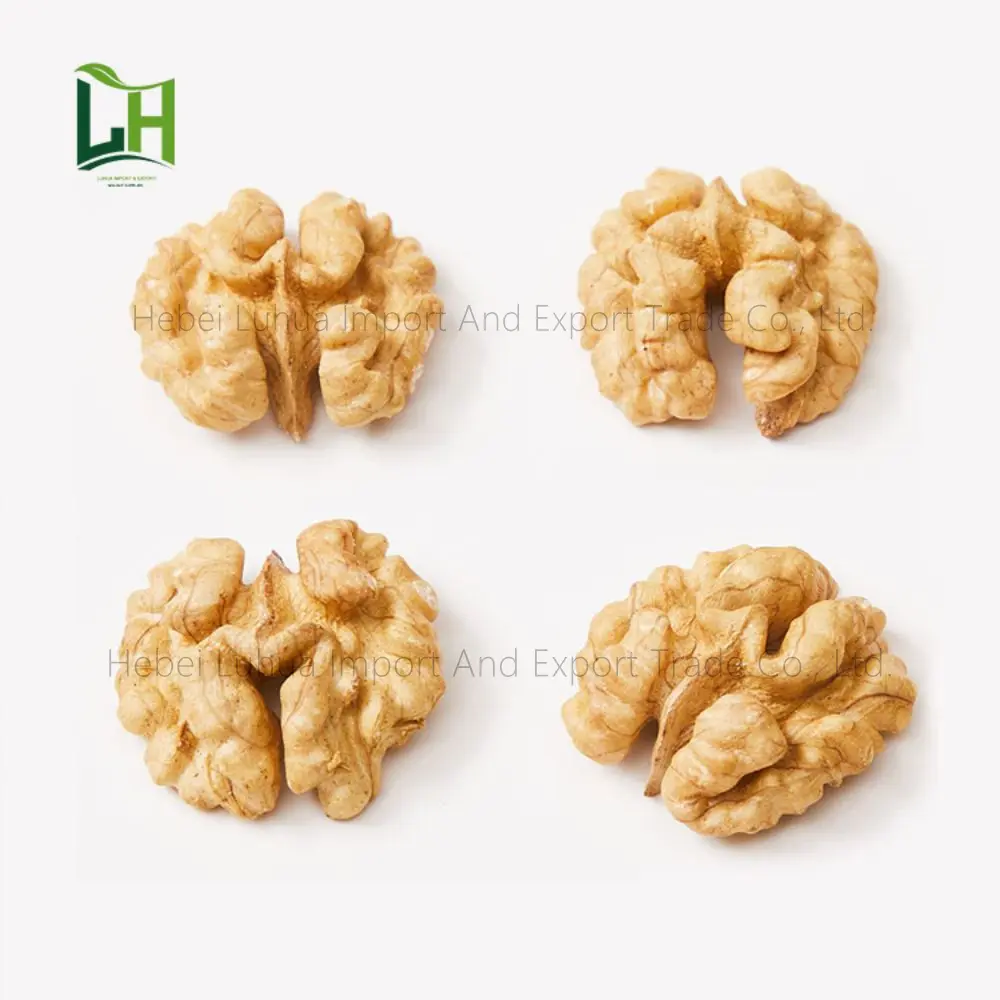

When sourcing shelled walnuts, understanding the distinctions between different grades is crucial for matching the product to specific application requirements. Our primary offerings, Yunnan Walnut Kernels Extra Light Halves (ELH) and Light Halves (LH), represent the pinnacle of quality, with subtle differences in color and integrity. The following comparison highlights their characteristics, aiding B2B buyers in making informed procurement decisions for their specific needs, whether for premium baking or broader food manufacturing.

| Feature | Yunnan ELH (Extra Light Halves) | Yunnan LH (Light Halves) | Ideal Application |

|---|---|---|---|

| Color | Very light, creamy white to golden. Extremely uniform. | Light tan to amber. Good uniformity. | Visual appeal in products. |

| Halves Integrity | Min 80% halves, max 3% broken pieces. | Min 70% halves, max 5% broken pieces. | Product presentation (e.g., toppings). |

| Flavor Profile | Mild, sweet, and buttery. | Rich, nutty, and slightly more robust. | Specific taste requirements. |

| Price Point | Premium (due to rigorous sorting and visual appeal). | Standard premium. | Budget vs. quality balance. |

| Certifications | ISO, HACCP, BRC (same for both, assuring baseline quality). | ISO, HACCP, BRC. | Food safety and compliance. |

While ELH walnuts command a higher price point due to their stringent color and integrity standards, they are unmatched for applications where visual appeal is paramount, such as high-end confectionery garnishes or transparent packaging. LH walnuts offer a robust flavor profile and excellent functionality at a slightly more accessible price, making them ideal for baking, internal mixes, or ground applications where color is less critical. Both grades ensure superior taste and nutritional value compared to lower-grade unshelled walnuts or lesser processed kernels, representing a commitment to quality whether you need a walnut 1 kg without shell sample or multi-ton shipments.

Custom Solutions and Client-Centric Approach

Recognizing that every B2B client has unique requirements, LuHua Walnut offers highly customizable solutions for their procurement of high-quality shelled walnuts. Our technical team works closely with procurement and R&D departments to define specific product parameters, including desired kernel size fractions (e.g., halves, pieces, small pieces), moisture content adjustments for specific processing needs, or specialized packaging formats. Whether you require distinct certifications, specific packaging sizes beyond the standard walnut 1 kg without shell, or unique logistical arrangements, our flexible approach ensures your operational needs are met without compromising on quality.

Our R&D capabilities also extend to developing blends of various kernel sizes or grades to achieve specific functional or cost objectives for our clients. For instance, a major cereal manufacturer needed a precise blend of light pieces and halves for consistent texture and visual appeal in their breakfast products; we developed a tailored solution that optimized their production line efficiency. This collaborative methodology ensures that our Yunnan Walnut Kernels integrate seamlessly into your existing manufacturing processes, providing optimized performance and value.

Application Case Study: Enhancing Nutritional Snack Bars

A leading health food brand, specializing in high-protein snack bars, faced challenges with inconsistent quality and high breakage rates from their previous supplier of shelled walnuts. This led to issues in product uniformity and increased waste during production. Upon partnering with LuHua Walnut, they transitioned to our Yunnan Walnut Kernels Light Halves (LH) grade. Our consistent quality, particularly the low percentage of broken pieces (max 5%), significantly improved their production efficiency and the visual appeal of their finished snack bars.

The brand reported a 10% reduction in production line downtime related to foreign material removal and a 7% increase in batch consistency. Furthermore, the stable moisture content and low peroxide value of our kernels ensured a longer shelf life for their snack bars, leading to reduced returns and enhanced consumer satisfaction. This case exemplifies how LuHua Walnut's commitment to technical excellence and stringent quality control directly contributes to the success and reputation of our B2B partners across various demanding applications. This client initially started with a trial order of walnut 1 kg without shell to test compatibility, which quickly scaled into a long-term supply contract.

Authoritativeness and Certifications

LuHua Walnut's reputation for supplying premium shelled walnuts is underpinned by our robust commitment to international quality and safety standards. Our facilities and processes are certified under multiple globally recognized schemes, providing our partners with complete assurance. We strictly adhere to ISO 22000, ensuring a comprehensive food safety management system that covers the entire supply chain. Our HACCP (Hazard Analysis and Critical Control Points) certification rigorously addresses food safety hazards, from biological to chemical and physical.

Furthermore, our compliance with BRC Global Standards for Food Safety, a benchmark for best practice in the food industry, signifies our dedication to operational excellence, product integrity, and consumer protection. These certifications are regularly audited by independent third-party bodies, ensuring ongoing adherence to the highest standards. Our long-standing partnerships with global food manufacturers, some spanning over a decade, further attest to our reliability and consistent delivery of high-quality products, whether it's Extra Light Halves for premium confectionery or bulk walnut 1 kg without shell orders for snack production.

(Image for illustrative purposes, actual certifications may vary)

(Image for illustrative purposes, actual certifications may vary)

Trustworthiness: FAQ, Delivery, and Support

Frequently Asked Questions (FAQ)

- Q: What is the typical shelf life of your shelled walnuts?

A: When stored in a cool, dry place (ideally 0-4°C / 32-40°F) and in original sealed packaging, our walnuts have a shelf life of 12-24 months. - Q: Can you provide samples before a bulk order?

A: Yes, we offer samples for B2B clients to evaluate our product quality, including walnut 1 kg without shell samples, to ensure they meet your specifications. - Q: What are your minimum order quantities (MOQ)?

A: MOQs vary depending on the product grade and packaging. Please contact our sales team for detailed information tailored to your needs. - Q: Do you offer different packaging options?

A: Yes, we provide various packaging options, including vacuum-sealed bags, nitrogen-flushed bags, and bulk cartons, to ensure product freshness and align with your logistical requirements.

Delivery and Logistics

We operate an efficient global logistics network to ensure timely and secure delivery of our shelled walnuts worldwide. Our standard delivery lead time typically ranges from 15 to 30 days depending on the destination and order volume, commencing from order confirmation. We work with trusted freight partners to ensure optimal transport conditions, maintaining product integrity from our facility to yours. Expedited shipping options are available upon request for urgent requirements.

Quality Assurance and Customer Support

LuHua Walnut stands behind the quality of our Yunnan Walnut Kernels with a comprehensive quality assurance policy. All products are delivered with a Certificate of Analysis (COA) confirming adherence to agreed specifications. In the unlikely event of any quality discrepancy, our dedicated customer support team is available to address concerns promptly and professionally, ensuring satisfactory resolution. Our commitment extends beyond delivery, fostering long-term partnerships built on reliability and mutual trust.

Conclusion: Your Trusted Partner for Premium Shelled Walnuts

As the demand for high-quality shelled walnuts continues to grow across diverse industries, selecting a reliable and technically proficient supplier is paramount. LuHua Walnut is committed to delivering excellence through our meticulously processed Yunnan Walnut Kernels, offering superior grades like Extra Light Halves (ELH) and Light Halves (LH). Our vertical integration, advanced processing technologies, and unwavering adherence to global food safety standards ensure that every shipment meets the most stringent B2B requirements. Partner with us to elevate your products with consistently fresh, flavorful, and nutritionally rich walnut kernels.

References

- Smith, J. (2022). "Global Nut Market Trends: A Focus on Walnut Kernel Demand." Journal of Food Industry Insights.

- Walnut Council. (2021). "Best Practices in Walnut Processing and Storage." Industry Best Practice Guidelines.

- International Nut and Dried Fruit Council (INC). (2023). "Global Statistical Review 2022/2023." INC Publications.

- Food Safety and Standards Authority of India (FSSAI). (2020). "Manual of Methods of Analysis of Foods – Nuts and Nut Products." FSSAI Guidelines.

- U.S. Department of Agriculture (USDA). (2023). "Agricultural Marketing Service - Walnut Quality Standards." USDA Publications.

Post time:Aug . 13, 2025 06:00