Driving Demand for Premium Walnuts: Insights into Walnut Kernel Light Halves

In the dynamic global market for healthy ingredients, the demand for convenient, high-quality nut products continues to soar. Among these, walnut 1 kg without shell, particularly in the form of Light Halves, stands out as a staple for businesses ranging from bakeries and confectioneries to health food manufacturers. The convenience of pre-shelled walnuts significantly reduces preparation time and labor costs for industrial users, making them an indispensable component in modern food production. This segment of the market emphasizes consistent quality, precise specifications, and reliable supply chains, directly impacting the end product's appeal and nutritional value. The shift towards ready-to-use ingredients reflects a broader industry trend focusing on efficiency and product innovation.

The increasing consumer awareness regarding the health benefits of walnuts, rich in Omega-3 fatty acids, antioxidants, and essential minerals, further fuels this demand. As manufacturers look to incorporate more natural and wholesome ingredients, the integrity and purity of products like Walnut Kernel Light Halves become paramount. This article delves into the intricate details of sourcing, processing, and quality assurance for premium shelled walnuts, providing a comprehensive guide for B2B buyers seeking to optimize their supply chain and enhance their product offerings with superior walnut 1 kg without shell options. Understanding the nuances of origin, processing, and quality control is crucial for making informed purchasing decisions in this competitive landscape.

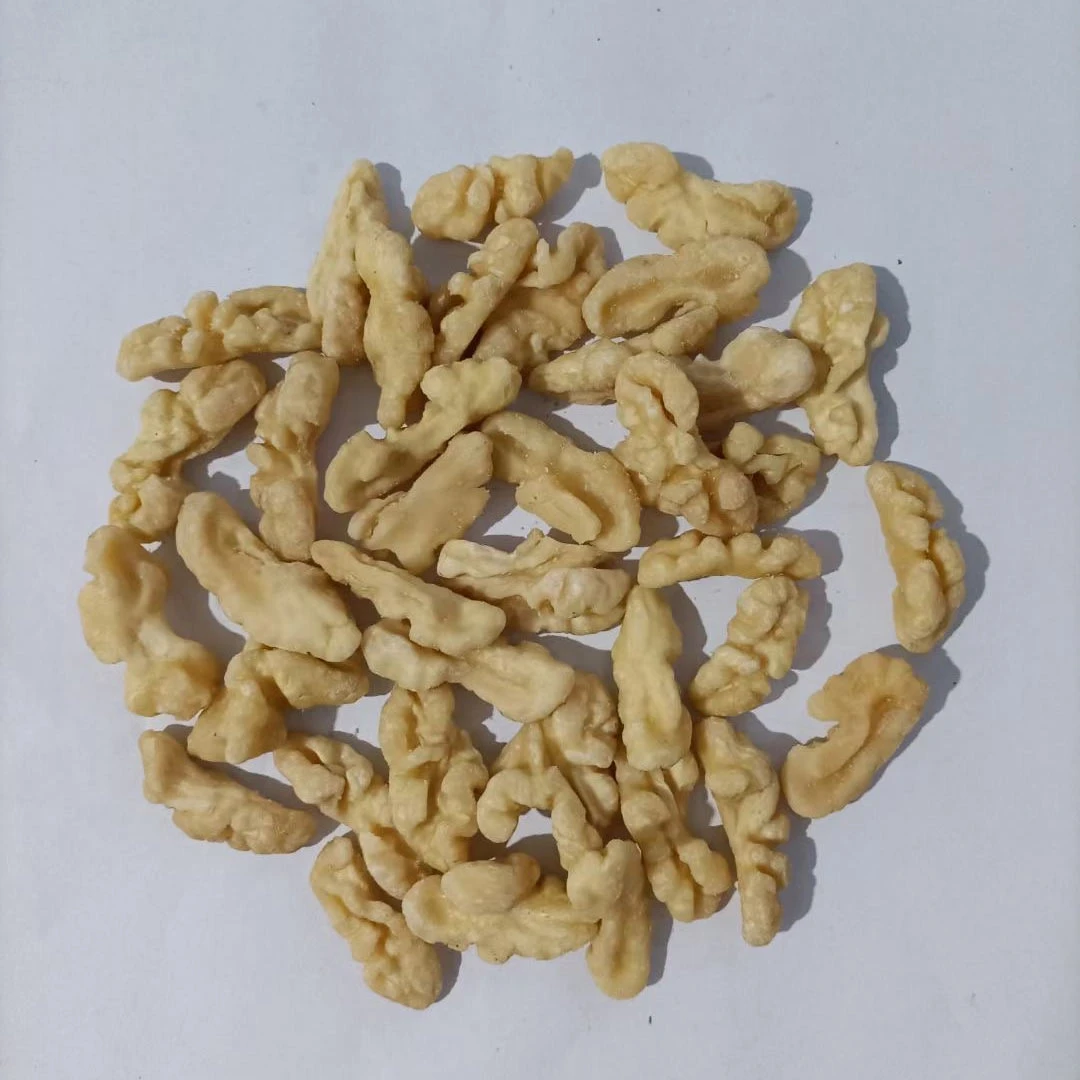

Figure 1: Premium Walnut Kernels ready for quality inspection.

The Manufacturing Process: Ensuring Premium Quality Walnut Kernel Light Halves

The production of high-quality walnut 1 kg without shell, specifically Light Halves, involves a meticulous multi-stage process designed to preserve nutritional integrity, ensure food safety, and deliver consistent visual appeal. It begins with the careful harvesting of mature walnuts, typically from prime growing regions known for their superior cultivars. Once harvested, the in-shell walnuts undergo an initial cleaning to remove debris.

Key Processing Stages:

- Cracking: Specialized machinery is used to gently crack the hard outer shells, minimizing damage to the delicate kernels. This step is crucial for yielding a high percentage of whole or half kernels.

- Shell Separation: After cracking, an advanced separation process, often involving air currents and vibratory screens, removes shell fragments from the kernels. This ensures a clean walnut no shell product.

- Sorting & Grading: Kernels are then sorted by size, color (light, amber), and form (halves, pieces, crumbles) using both optical sorting machines and manual inspection. The "Light Halves" grade specifically refers to kernels that retain at least half of their original shape and exhibit a pale, desirable color.

- Drying & Moisture Control: To ensure shelf stability and prevent spoilage, kernels are carefully dried to achieve optimal moisture content, typically below 6%. This process is critical for preserving flavor and texture without over-drying.

- Quality Control & Inspection: Each batch undergoes rigorous quality checks, including sensory evaluation, microbiological testing (e.g., for E. coli, Salmonella), and testing for mycotoxins like Aflatoxin. Physical parameters such as foreign matter, shriveled kernels, and insect damage are also meticulously inspected. This adherence to strict standards ensures that the final walnut without shell product meets international food safety guidelines.

- Packaging: Finally, the graded and inspected walnuts are hygienically packaged, often in vacuum-sealed bags or modified atmosphere packaging (MAP), to maintain freshness and extend shelf life. Packaging in quantities like walnut 1 kg without shell is common for bulk B2B distribution.

Manufacturers adhere to internationally recognized standards such as ISO 22000 (Food Safety Management Systems), HACCP (Hazard Analysis and Critical Control Points), and often comply with FDA regulations for imports. The typical shelf life for properly stored Walnut Kernel Light Halves is 12-18 months when kept in cool, dry conditions, preferably refrigerated. This meticulous process ensures that the product delivered to industries such as bakeries, confectioneries, snack food producers, and health supplement manufacturers is not only safe and delicious but also provides significant advantages in terms of convenience and reduced processing waste, contributing to greater efficiency and lower operational costs.

Technical Specifications & Nutritional Profile: Walnut Kernel Light Halves

For B2B buyers, understanding the precise technical specifications and nutritional composition of walnut 1 kg without shell is crucial for product formulation and quality assurance. These specifications define the quality, purity, and consistency of the Light Halves, ensuring they meet the stringent requirements of industrial applications. The table below outlines typical parameters for high-grade Walnut Kernel Light Halves.

| Parameter | Typical Value (Light Halves) | Description / Standard |

|---|---|---|

| Appearance | Light golden to amber, characteristic half kernel shape | Visual appeal for bakery and confectionery; consistent color for product uniformity. |

| Moisture Content | Max 6.0% | Critical for shelf life and preventing mold growth. Lower moisture increases stability. |

| Broken Rate | Max 5.0% (for Light Halves) | Percentage of kernels not meeting the "half" definition. Lower is better for visual quality. |

| Foreign Matter | Max 0.01% | Any non-walnut material (e.g., shell fragments, dust). Must be minimal for food safety. |

| Defective Kernels | Max 1.0% (e.g., shriveled, discolored, insect damaged) | Ensures overall quality and taste profile. |

| Peroxide Value (PV) | Max 5 meq O2/kg fat | Indicator of fat oxidation (rancidity). Lower PV indicates fresher product. |

| Aflatoxin | Max 4 ppb (B1) / Max 10 ppb (Total) - EU Standard | Critical food safety parameter, often subject to strict regulatory limits. |

| Nutritional Value (per 100g) | Energy: ~654 kcal Protein: ~15g Fat: ~65g (Omega-3: ~9g) Carbohydrates: ~14g Fiber: ~7g |

Highlighting health benefits for product labeling and consumer appeal. |

These parameters are critical for consistent product performance and meeting regulatory compliance worldwide. Reputable suppliers provide Certificates of Analysis (CoA) with each batch, detailing these specifications to guarantee the quality of the walnut without shell product. The high content of Omega-3 fatty acids, particularly alpha-linolenic acid (ALA), makes walnuts a valuable ingredient for heart-healthy and brain-boosting food products, aligning with current consumer health trends. The low moisture content ensures extended shelf life and prevents microbial growth, which is essential for large-scale industrial use.

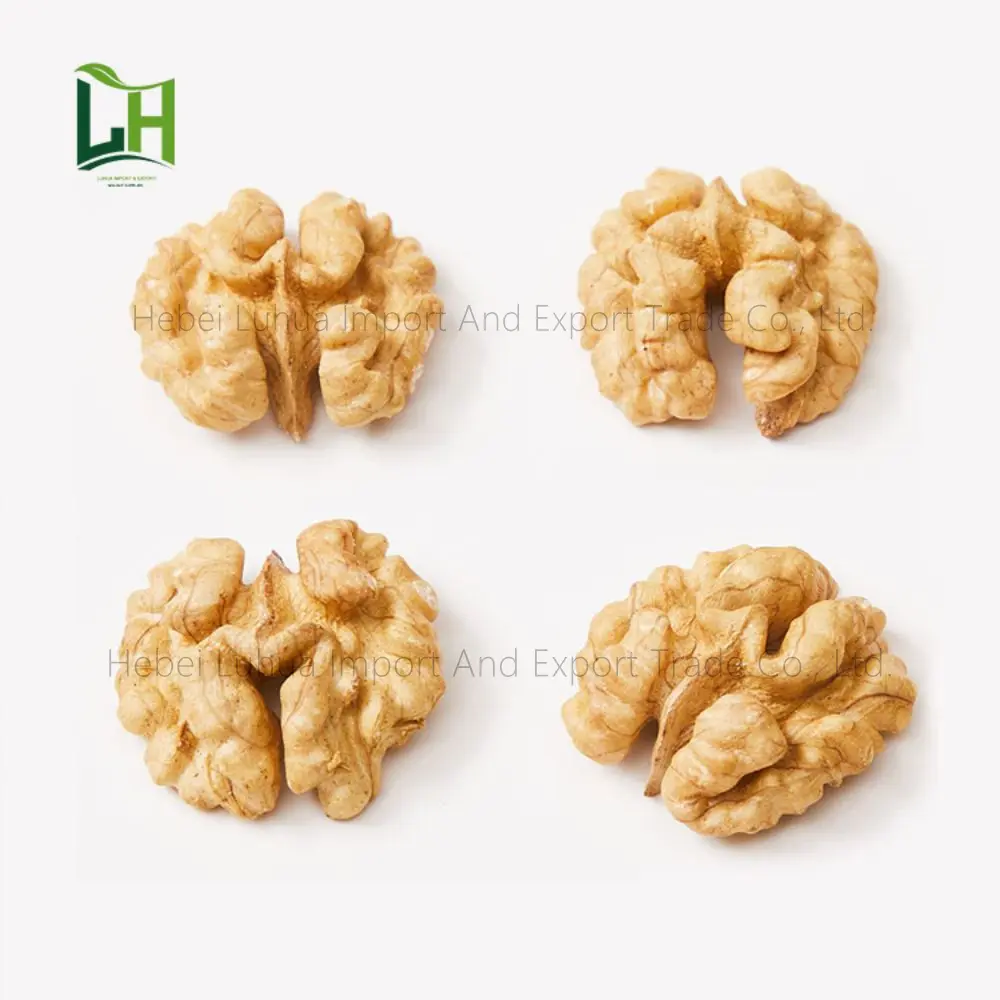

Figure 2: Advanced sorting machinery ensures high purity for shelled walnuts.

Application Scenarios & Advantages for B2B Clients

The versatility of walnut 1 kg without shell, particularly in the form of Light Halves, makes it an invaluable ingredient across diverse industrial applications. Its consistent quality, convenience, and nutritional profile offer significant advantages for B2B clients looking to enhance their product offerings.

Key Application Industries:

- Bakery & Confectionery: Walnuts are a classic addition to breads, cakes, cookies, brownies, and pastries. Light Halves maintain their structure during baking, providing appealing visual texture and rich flavor. They are also popular in chocolate bars, pralines, and other sweet treats.

- Snack Food Industry: As a healthy snack on their own or mixed with dried fruits and other nuts, walnut no shell options are highly sought after. They can be roasted, flavored, or candied for unique snack products.

- Breakfast Cereals & Granola: Adding walnut halves to cereals, granolas, and muesli provides a crunchy texture, healthy fats, and increased nutritional value, appealing to health-conscious consumers.

- Dairy & Ice Cream: Chopped or whole walnuts are integrated into yogurts, ice creams, and other dairy desserts, contributing a distinctive nutty flavor and satisfying crunch.

- Ready-to-Eat Meals & Salads: For convenience food manufacturers, pre-shelled walnuts are ideal for adding to salads, pasta dishes, or as a garnish for various ready-to-eat meals, boosting both nutrition and appeal.

- Plant-Based & Health Food Products: Given their plant-based protein and healthy fat content, walnuts are a cornerstone in vegan products, nut milks, and various health supplements.

Technical Advantages for Businesses:

- Cost-Efficiency & Labor Savings: Utilizing walnut without shell eliminates the need for shelling equipment and associated labor, significantly reducing operational costs and production time for food manufacturers. This directly translates to increased throughput and profitability.

- Consistent Quality & Reduced Waste: Sourcing from reputable suppliers ensures uniform size, color, and quality of Light Halves, minimizing waste from substandard kernels and contributing to a more consistent final product.

- Enhanced Food Safety: Industrial-scale processing includes stringent sorting and quality control measures, reducing the risk of foreign matter contamination and ensuring compliance with food safety regulations. This provides peace of mind for B2B clients concerning product integrity.

- Extended Shelf Life: Proper drying and packaging methods, such as vacuum-sealing for walnut 1 kg without shell, contribute to a longer shelf life, reducing spoilage and inventory management challenges.

- Formulation Flexibility: Available in various grades (halves, pieces, crumbles) and packaging sizes, shelled walnuts offer flexibility for different product formulations and applications, allowing manufacturers to innovate and diversify their offerings.

These advantages underscore why manufacturers prioritize high-quality, pre-shelled walnuts as a key component in their ingredient procurement strategy. The shift towards ready-to-use ingredients is not just a trend but a fundamental aspect of modern food production, where efficiency, consistency, and safety are paramount.

Why Choose Us? Expertise, Authoritativeness, and Trustworthiness

Selecting the right supplier for bulk walnut 1 kg without shell is a critical decision for any food manufacturing business. Our commitment to expertise, authoritativeness, and trustworthiness ensures that you receive only the highest quality Walnut Kernel Light Halves, backed by rigorous standards and exceptional service.

Our Credentials and Quality Assurance:

- Industry Certifications: We operate under strict adherence to international food safety standards, including ISO 22000, HACCP, and GMP (Good Manufacturing Practices). Our facilities are regularly audited to ensure compliance, providing a guarantee of safety and quality for every batch of walnut no shell.

- Decades of Experience: With extensive experience in the walnut industry, we possess deep knowledge of cultivation, processing, and market demands. This expertise allows us to consistently deliver superior products and anticipate market trends.

- Rigorous Testing: Every shipment undergoes comprehensive laboratory testing for moisture content, purity, microbiological parameters (e.g., total plate count, coliforms, yeast & mold), and critical contaminants like Aflatoxin and heavy metals. Certificates of Analysis (CoA) are provided with each order, offering transparent data on product specifications.

- Traceability: Our robust traceability system ensures that every walnut without shell batch can be traced back to its origin, from farm to your facility, ensuring accountability and rapid response in case of any quality concerns.

- Customer Feedback & Success Stories: We pride ourselves on long-standing partnerships with leading food manufacturers globally. Our clients consistently report enhanced product quality and improved operational efficiency due to our reliable supply of premium walnuts. For example, a major bakery chain reported a 15% reduction in production time after switching to our pre-sorted Light Halves.

Logistics, Support & Guarantees:

- Efficient Delivery Cycle: We maintain strong supply chain logistics, ensuring timely and efficient delivery. Our typical lead time for international orders is 2-4 weeks, subject to destination and order volume, with expedited options available for urgent requirements.

- Quality Assurance & Warranty: We guarantee the quality and freshness of our walnut 1 kg without shell products upon arrival, provided they are stored according to recommended conditions. Any discrepancies are handled swiftly and professionally by our dedicated customer support team.

- Dedicated Customer Support: Our team of technical and sales experts is available to provide guidance on product specifications, application advice, and logistical support, ensuring a seamless procurement process from inquiry to delivery.

Frequently Asked Questions (FAQ):

- Q: What is the typical shelf life of your Walnut Kernel Light Halves?

A: When stored in cool (0-4°C), dry conditions, preferably refrigerated, our walnuts have a shelf life of 12-18 months in their original sealed packaging. - Q: Are your walnuts allergen-free from other nuts?

A: Walnuts are tree nuts and are themselves an allergen. Our facilities handle tree nuts. While we employ strict cleaning protocols, we advise clients to consider cross-contamination risks for highly sensitive individuals, as per industry best practices. - Q: Can you provide samples for testing?

A: Yes, we offer samples for qualified B2B clients to evaluate our product quality before making a bulk purchase decision. Please contact our sales team to arrange this. - Q: What are your minimum order quantities (MOQ)?

A: MOQs vary based on product grade and packaging. Please contact our sales representatives for specific details tailored to your requirements for walnut 1 kg without shell or other quantities.

Figure 3: Secure and hygienic packaging for bulk orders.

Custom Solutions and Future Outlook for Shelled Walnuts

Recognizing the diverse needs of the B2B market, we offer flexible and customized solutions beyond standard walnut 1 kg without shell packaging. Our capabilities extend to providing various grades of walnut kernels (e.g., Light Halves, Light Pieces, Light Crumbs) and custom packaging sizes to suit specific production lines and storage requirements. Whether you require particular moisture levels, specific sizing for automation, or tailored packaging for direct retail, our team can work with you to develop a bespoke supply solution. This flexibility is key to enabling our partners to innovate and expand their product lines efficiently.

The market for walnut without shell is poised for continued growth, driven by increasing consumer demand for natural, healthy, and convenient food options. As global awareness of the nutritional benefits of walnuts grows, so too will the opportunities for food manufacturers to incorporate this versatile ingredient into new and existing products. We are committed to staying at the forefront of this evolving market, continually investing in advanced processing technologies and sustainable sourcing practices to ensure a consistent supply of premium quality walnuts. Our goal is to empower our B2B partners with the best possible ingredients to meet and exceed consumer expectations.

References

- Ros, E. (2010). Health benefits of nuts in prevention and management of diabetes. Current Opinion in Clinical Nutrition and Metabolic Care, 13(4), 438-444.

- Sabate, J., & Fraser, G. E. (2009). Nuts: a new dietary recommendation for health and disease. Asia Pacific Journal of Clinical Nutrition, 18(4), 543-550.

- Chen, H. K., Chou, Y. T., & Chen, H. H. (2015). Aflatoxin contamination in walnuts: a review. Food Control, 53, 1-7.

- USDA FoodData Central. (n.d.). Walnuts, English. Retrieved from [Relevant USDA database entry - e.g., National Nutrient Database].

- Food and Agriculture Organization of the United Nations (FAO). (n.d.). Post-harvest operations for walnuts. Retrieved from [Relevant FAO publication/guidelines].

The Manufacturing Process: Ensuring Premium Quality Walnut Kernel Light Halves

The production of high-quality walnut 1 kg without shell, specifically Light Halves, involves a meticulous multi-stage process designed to preserve nutritional integrity, ensure food safety, and deliver consistent visual appeal. It begins with the careful harvesting of mature walnuts, typically from prime growing regions known for their superior cultivars. Once harvested, the in-shell walnuts undergo an initial cleaning to remove debris.

Key Processing Stages:

- Cracking: Specialized machinery is used to gently crack the hard outer shells, minimizing damage to the delicate kernels. This step is crucial for yielding a high percentage of whole or half kernels.

- Shell Separation: After cracking, an advanced separation process, often involving air currents and vibratory screens, removes shell fragments from the kernels. This ensures a clean walnut no shell product.

- Sorting & Grading: Kernels are then sorted by size, color (light, amber), and form (halves, pieces, crumbles) using both optical sorting machines and manual inspection. The "Light Halves" grade specifically refers to kernels that retain at least half of their original shape and exhibit a pale, desirable color.

- Drying & Moisture Control: To ensure shelf stability and prevent spoilage, kernels are carefully dried to achieve optimal moisture content, typically below 6%. This process is critical for preserving flavor and texture without over-drying.

- Quality Control & Inspection: Each batch undergoes rigorous quality checks, including sensory evaluation, microbiological testing (e.g., for E. coli, Salmonella), and testing for mycotoxins like Aflatoxin. Physical parameters such as foreign matter, shriveled kernels, and insect damage are also meticulously inspected. This adherence to strict standards ensures that the final walnut without shell product meets international food safety guidelines.

- Packaging: Finally, the graded and inspected walnuts are hygienically packaged, often in vacuum-sealed bags or modified atmosphere packaging (MAP), to maintain freshness and extend shelf life. Packaging in quantities like walnut 1 kg without shell is common for bulk B2B distribution.

Manufacturers adhere to internationally recognized standards such as ISO 22000 (Food Safety Management Systems), HACCP (Hazard Analysis and Critical Control Points), and often comply with FDA regulations for imports. The typical shelf life for properly stored Walnut Kernel Light Halves is 12-18 months when kept in cool, dry conditions, preferably refrigerated. This meticulous process ensures that the product delivered to industries such as bakeries, confectioneries, snack food producers, and health supplement manufacturers is not only safe and delicious but also provides significant advantages in terms of convenience and reduced processing waste, contributing to greater efficiency and lower operational costs.

Technical Specifications & Nutritional Profile: Walnut Kernel Light Halves

For B2B buyers, understanding the precise technical specifications and nutritional composition of walnut 1 kg without shell is crucial for product formulation and quality assurance. These specifications define the quality, purity, and consistency of the Light Halves, ensuring they meet the stringent requirements of industrial applications. The table below outlines typical parameters for high-grade Walnut Kernel Light Halves.

| Parameter | Typical Value (Light Halves) | Description / Standard |

|---|---|---|

| Appearance | Light golden to amber, characteristic half kernel shape | Visual appeal for bakery and confectionery; consistent color for product uniformity. |

| Moisture Content | Max 6.0% | Critical for shelf life and preventing mold growth. Lower moisture increases stability. |

| Broken Rate | Max 5.0% (for Light Halves) | Percentage of kernels not meeting the "half" definition. Lower is better for visual quality. |

| Foreign Matter | Max 0.01% | Any non-walnut material (e.g., shell fragments, dust). Must be minimal for food safety. |

| Defective Kernels | Max 1.0% (e.g., shriveled, discolored, insect damaged) | Ensures overall quality and taste profile. |

| Peroxide Value (PV) | Max 5 meq O2/kg fat | Indicator of fat oxidation (rancidity). Lower PV indicates fresher product. |

| Aflatoxin | Max 4 ppb (B1) / Max 10 ppb (Total) - EU Standard | Critical food safety parameter, often subject to strict regulatory limits. |

| Nutritional Value (per 100g) | Energy: ~654 kcal Protein: ~15g Fat: ~65g (Omega-3: ~9g) Carbohydrates: ~14g Fiber: ~7g |

Highlighting health benefits for product labeling and consumer appeal. |

These parameters are critical for consistent product performance and meeting regulatory compliance worldwide. Reputable suppliers provide Certificates of Analysis (CoA) with each batch, detailing these specifications to guarantee the quality of the walnut without shell product. The high content of Omega-3 fatty acids, particularly alpha-linolenic acid (ALA), makes walnuts a valuable ingredient for heart-healthy and brain-boosting food products, aligning with current consumer health trends. The low moisture content ensures extended shelf life and prevents microbial growth, which is essential for large-scale industrial use.

Figure 2: Advanced sorting machinery ensures high purity for shelled walnuts.

Application Scenarios & Advantages for B2B Clients

The versatility of walnut 1 kg without shell, particularly in the form of Light Halves, makes it an invaluable ingredient across diverse industrial applications. Its consistent quality, convenience, and nutritional profile offer significant advantages for B2B clients looking to enhance their product offerings.

Key Application Industries:

- Bakery & Confectionery: Walnuts are a classic addition to breads, cakes, cookies, brownies, and pastries. Light Halves maintain their structure during baking, providing appealing visual texture and rich flavor. They are also popular in chocolate bars, pralines, and other sweet treats.

- Snack Food Industry: As a healthy snack on their own or mixed with dried fruits and other nuts, walnut no shell options are highly sought after. They can be roasted, flavored, or candied for unique snack products.

- Breakfast Cereals & Granola: Adding walnut halves to cereals, granolas, and muesli provides a crunchy texture, healthy fats, and increased nutritional value, appealing to health-conscious consumers.

- Dairy & Ice Cream: Chopped or whole walnuts are integrated into yogurts, ice creams, and other dairy desserts, contributing a distinctive nutty flavor and satisfying crunch.

- Ready-to-Eat Meals & Salads: For convenience food manufacturers, pre-shelled walnuts are ideal for adding to salads, pasta dishes, or as a garnish for various ready-to-eat meals, boosting both nutrition and appeal.

- Plant-Based & Health Food Products: Given their plant-based protein and healthy fat content, walnuts are a cornerstone in vegan products, nut milks, and various health supplements.

Technical Advantages for Businesses:

- Cost-Efficiency & Labor Savings: Utilizing walnut without shell eliminates the need for shelling equipment and associated labor, significantly reducing operational costs and production time for food manufacturers. This directly translates to increased throughput and profitability.

- Consistent Quality & Reduced Waste: Sourcing from reputable suppliers ensures uniform size, color, and quality of Light Halves, minimizing waste from substandard kernels and contributing to a more consistent final product.

- Enhanced Food Safety: Industrial-scale processing includes stringent sorting and quality control measures, reducing the risk of foreign matter contamination and ensuring compliance with food safety regulations. This provides peace of mind for B2B clients concerning product integrity.

- Extended Shelf Life: Proper drying and packaging methods, such as vacuum-sealing for walnut 1 kg without shell, contribute to a longer shelf life, reducing spoilage and inventory management challenges.

- Formulation Flexibility: Available in various grades (halves, pieces, crumbles) and packaging sizes, shelled walnuts offer flexibility for different product formulations and applications, allowing manufacturers to innovate and diversify their offerings.

These advantages underscore why manufacturers prioritize high-quality, pre-shelled walnuts as a key component in their ingredient procurement strategy. The shift towards ready-to-use ingredients is not just a trend but a fundamental aspect of modern food production, where efficiency, consistency, and safety are paramount.

Why Choose Us? Expertise, Authoritativeness, and Trustworthiness

Selecting the right supplier for bulk walnut 1 kg without shell is a critical decision for any food manufacturing business. Our commitment to expertise, authoritativeness, and trustworthiness ensures that you receive only the highest quality Walnut Kernel Light Halves, backed by rigorous standards and exceptional service.

Our Credentials and Quality Assurance:

- Industry Certifications: We operate under strict adherence to international food safety standards, including ISO 22000, HACCP, and GMP (Good Manufacturing Practices). Our facilities are regularly audited to ensure compliance, providing a guarantee of safety and quality for every batch of walnut no shell.

- Decades of Experience: With extensive experience in the walnut industry, we possess deep knowledge of cultivation, processing, and market demands. This expertise allows us to consistently deliver superior products and anticipate market trends.

- Rigorous Testing: Every shipment undergoes comprehensive laboratory testing for moisture content, purity, microbiological parameters (e.g., total plate count, coliforms, yeast & mold), and critical contaminants like Aflatoxin and heavy metals. Certificates of Analysis (CoA) are provided with each order, offering transparent data on product specifications.

- Traceability: Our robust traceability system ensures that every walnut without shell batch can be traced back to its origin, from farm to your facility, ensuring accountability and rapid response in case of any quality concerns.

- Customer Feedback & Success Stories: We pride ourselves on long-standing partnerships with leading food manufacturers globally. Our clients consistently report enhanced product quality and improved operational efficiency due to our reliable supply of premium walnuts. For example, a major bakery chain reported a 15% reduction in production time after switching to our pre-sorted Light Halves.

Logistics, Support & Guarantees:

- Efficient Delivery Cycle: We maintain strong supply chain logistics, ensuring timely and efficient delivery. Our typical lead time for international orders is 2-4 weeks, subject to destination and order volume, with expedited options available for urgent requirements.

- Quality Assurance & Warranty: We guarantee the quality and freshness of our walnut 1 kg without shell products upon arrival, provided they are stored according to recommended conditions. Any discrepancies are handled swiftly and professionally by our dedicated customer support team.

- Dedicated Customer Support: Our team of technical and sales experts is available to provide guidance on product specifications, application advice, and logistical support, ensuring a seamless procurement process from inquiry to delivery.

Frequently Asked Questions (FAQ):

- Q: What is the typical shelf life of your Walnut Kernel Light Halves?

A: When stored in cool (0-4°C), dry conditions, preferably refrigerated, our walnuts have a shelf life of 12-18 months in their original sealed packaging. - Q: Are your walnuts allergen-free from other nuts?

A: Walnuts are tree nuts and are themselves an allergen. Our facilities handle tree nuts. While we employ strict cleaning protocols, we advise clients to consider cross-contamination risks for highly sensitive individuals, as per industry best practices. - Q: Can you provide samples for testing?

A: Yes, we offer samples for qualified B2B clients to evaluate our product quality before making a bulk purchase decision. Please contact our sales team to arrange this. - Q: What are your minimum order quantities (MOQ)?

A: MOQs vary based on product grade and packaging. Please contact our sales representatives for specific details tailored to your requirements for walnut 1 kg without shell or other quantities.

Figure 3: Secure and hygienic packaging for bulk orders.

Custom Solutions and Future Outlook for Shelled Walnuts

Recognizing the diverse needs of the B2B market, we offer flexible and customized solutions beyond standard walnut 1 kg without shell packaging. Our capabilities extend to providing various grades of walnut kernels (e.g., Light Halves, Light Pieces, Light Crumbs) and custom packaging sizes to suit specific production lines and storage requirements. Whether you require particular moisture levels, specific sizing for automation, or tailored packaging for direct retail, our team can work with you to develop a bespoke supply solution. This flexibility is key to enabling our partners to innovate and expand their product lines efficiently.

The market for walnut without shell is poised for continued growth, driven by increasing consumer demand for natural, healthy, and convenient food options. As global awareness of the nutritional benefits of walnuts grows, so too will the opportunities for food manufacturers to incorporate this versatile ingredient into new and existing products. We are committed to staying at the forefront of this evolving market, continually investing in advanced processing technologies and sustainable sourcing practices to ensure a consistent supply of premium quality walnuts. Our goal is to empower our B2B partners with the best possible ingredients to meet and exceed consumer expectations.

References

- Ros, E. (2010). Health benefits of nuts in prevention and management of diabetes. Current Opinion in Clinical Nutrition and Metabolic Care, 13(4), 438-444.

- Sabate, J., & Fraser, G. E. (2009). Nuts: a new dietary recommendation for health and disease. Asia Pacific Journal of Clinical Nutrition, 18(4), 543-550.

- Chen, H. K., Chou, Y. T., & Chen, H. H. (2015). Aflatoxin contamination in walnuts: a review. Food Control, 53, 1-7.

- USDA FoodData Central. (n.d.). Walnuts, English. (Specific database entry would provide detailed nutritional values).

- Food and Agriculture Organization of the United Nations (FAO). (n.d.). Post-harvest operations for walnuts. (Relevant FAO publication or guidelines on nut processing).

Post time:Aug . 11, 2025 14:40