Market Overview & Industry Trends – Wholesale In-Shell Walnuts Gaining Global Demand

As global health trends drive demand for unprocessed, natural foods, whole walnuts for sale are seeing record interest, especially in bulk and wholesale formats such as walnuts in shell wholesale and walnuts in shell bulk. According to the International Nut & Dried Fruit Council (INC), global walnut production in 2023 exceeded 4.6 million tons, with China accounting for more than 50% of output, led by the Xinjiang region.

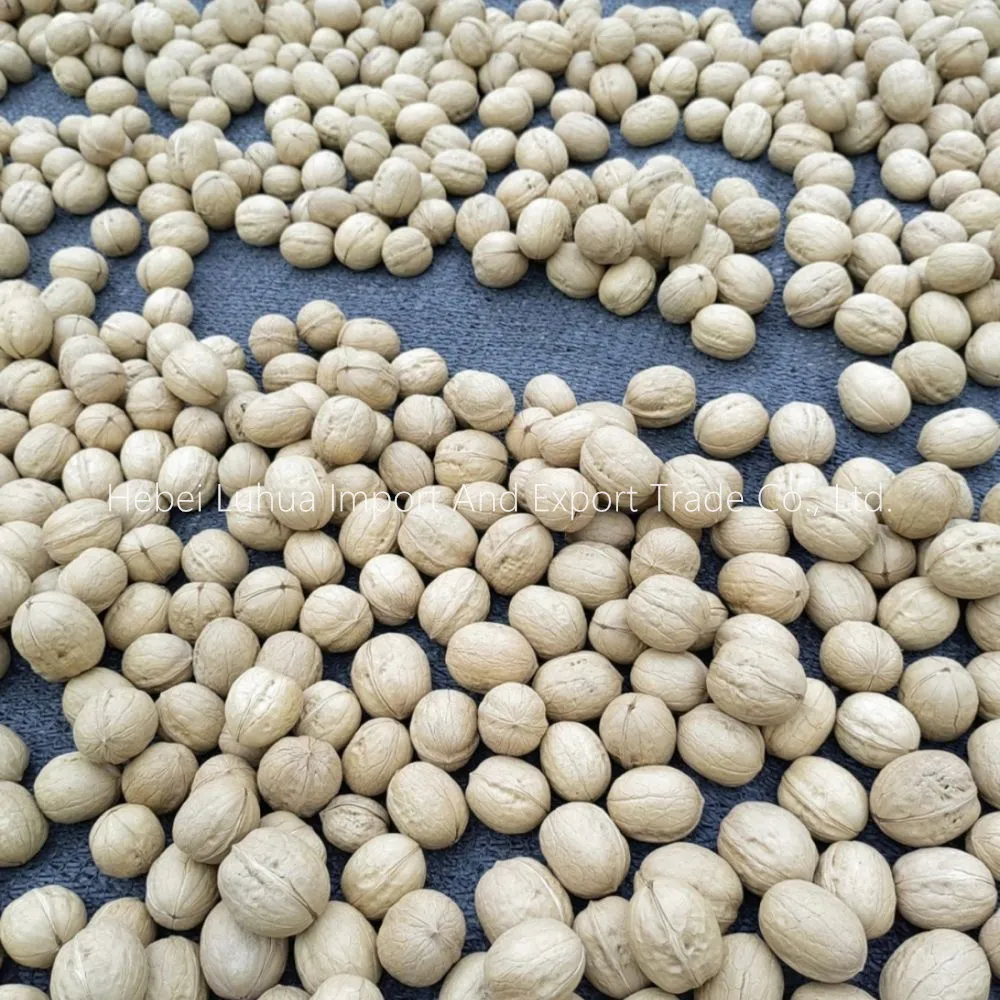

Major importers include the EU, India, and Turkey, focusing on high-quality, thin-shelled, easy-crack walnuts. Bulk buyers are now prioritizing traceability, organic certification, and consistent kernel yield. Xinjiang Thin-Skinned Walnuts, notably the "Xin 2" variety, have emerged as a preferred choice due to their superior kernel ratio and shell integrity.

| Brand/Origin | Kernel Yield (%) | Average Shell Thickness (mm) | Moisture (%) | Certification | TYPICAL SIZE (mm) |

|---|---|---|---|---|---|

| Xinjiang "Xin 2" | ≥58 | 1.0-1.2 | ≤7.5 | ISO22000, HACCP | 32-40 |

| California Chandler | 50-54 | 1.2-1.5 | ≤8.0 | USDA, FDA | 30-38 |

| Turkey Yalova | 47-52 | 1.3-1.6 | ≤8.5 | ISO22000 | 30-35 |

For up-to-date product specifications and whole walnuts for sale availability, visit Xinjiang Thin-Skinned Walnuts Xin 2 Walnuts In Shell.

Technical Parameter Trends: Visual Data for Whole Walnuts in Shell (Bulk/Wholesale)

Xinjiang Thin-Skinned Walnuts Xin 2 In Shell: Product Profile & Advantage Analysis

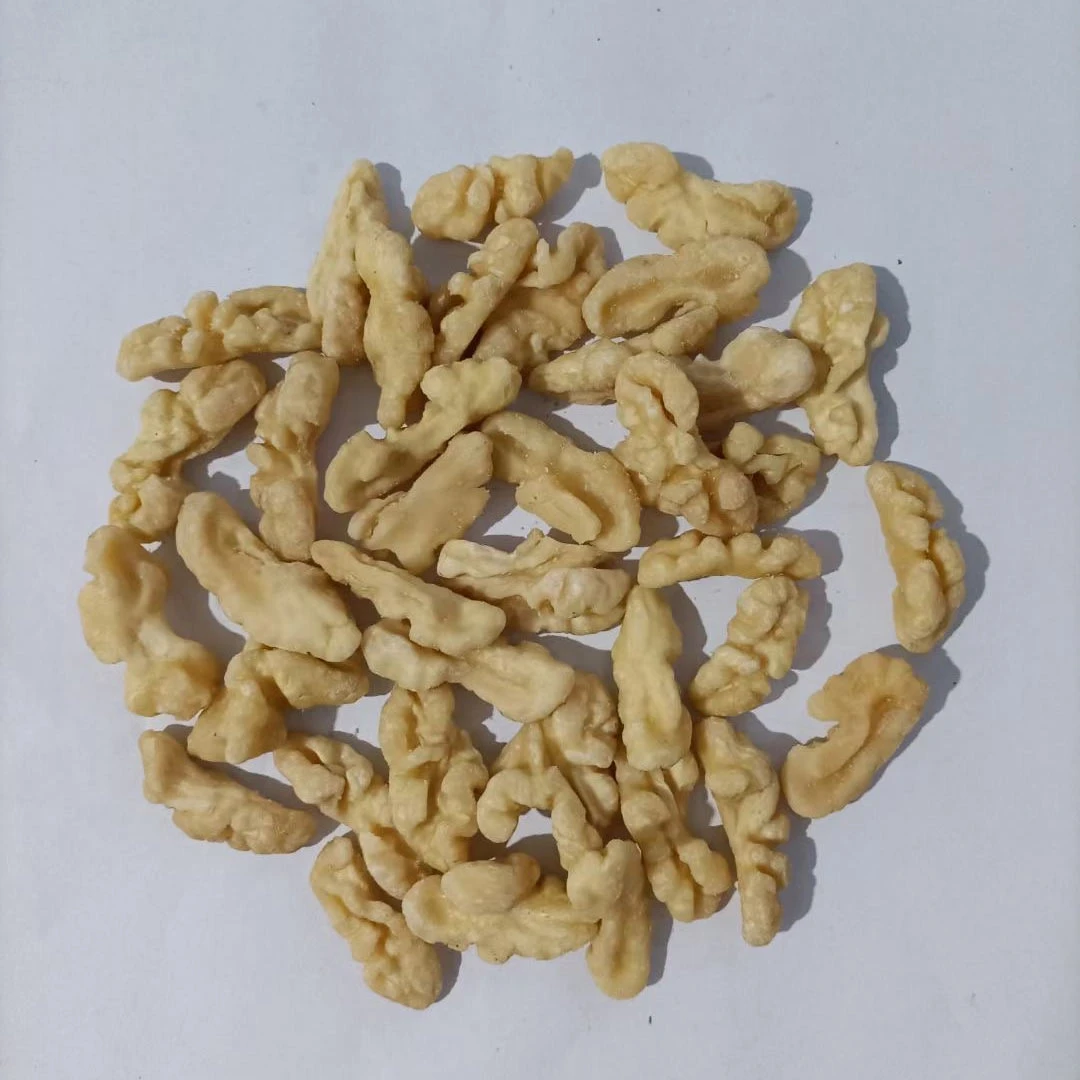

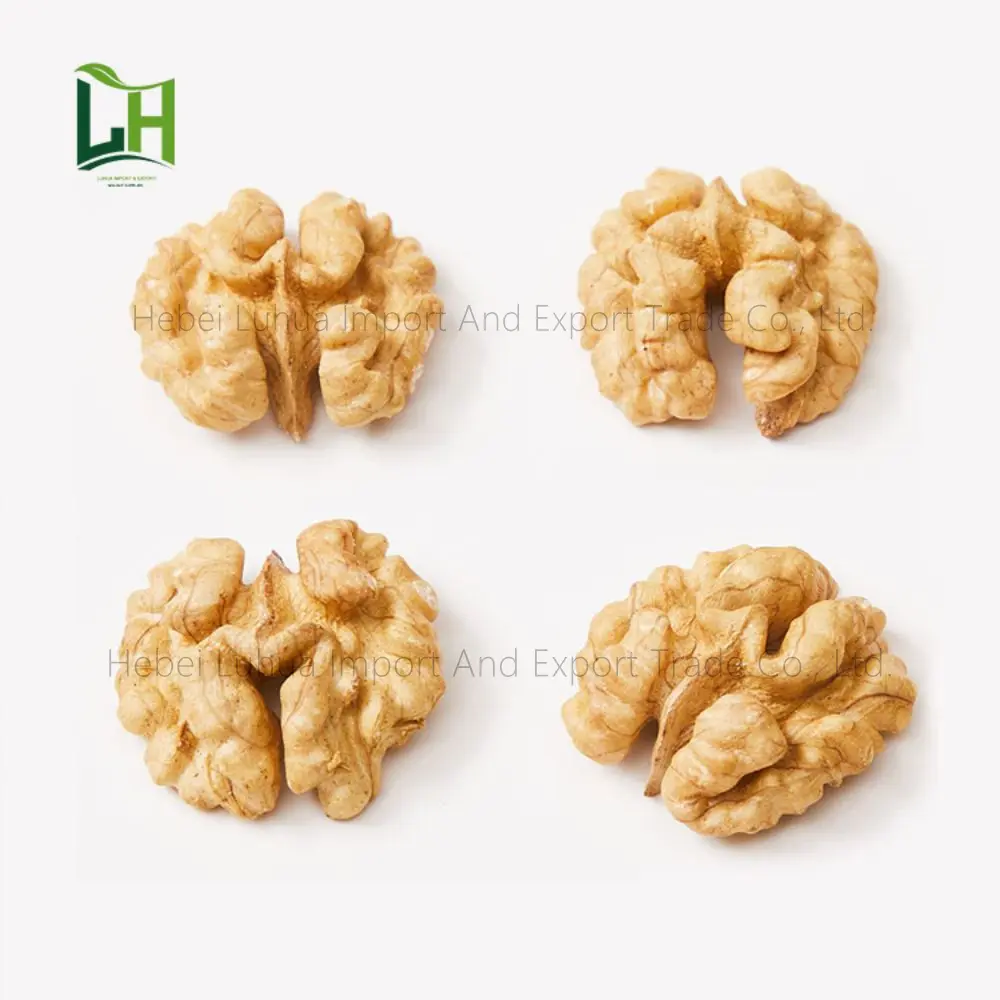

The Xinjiang Thin-Skinned Walnuts Xin 2 Walnuts In Shell (whole walnuts for sale) are a premium, export-grade product emphasizing:

- Material: Genetically selected, climate-optimized Juglans regia, with naturally thin shells (as low as 1.0 mm) but hard enough for international shipping.

- Processing: Advanced mechanical screening, ultrasonic cleaning, and controlled low-temperature dehydration.

- Quality Inspection: Each batch is ISO22000 and HACCP-certified, kernel yield laboratory-tested, and color/crack resistance is evaluated. Sampling according to GB1352/2011, FDA, and UNECE DDP-01 standards.

- Service Life & Shelf Stability: Due to ultra-low moisture and intact shells, in-shell walnuts maintain commercial viability for 12-18 months under dry warehouse conditions.

| Parameter | Xin 2 Walnut Spec | Test Standard |

|---|---|---|

| Shell Thickness | 1.0–1.2 mm | ISO 1352:2011 |

| Kernel Ratio | ≥58% | DDP-01 UNECE |

| Moisture Content | ≤7.5% | ISO22000/HACCP |

| Defects (Spots/Shrivel) | <2% | GB/T22167-2008 |

| Typical Diameter | 32–40mm | Caliper Gauge |

| Impurity (%) | <0.2% | ISO16000 |

Manufacturing Process Flow: Whole Walnuts for Sale Production Line

- Raw Walnut Harvesting: Manual & mechanical shaking, harvest at optimal maturity (28-32% initial moisture).

- Pre-cleaning & Sorting: Air blowers, vibration screens remove field debris and undersized nuts.

- Shell Separation & Calibration: Laser sorting for crack detection. Sizing by diameter (32–40mm).

- Ultrasonic Washing: Gentle, residue-free cleaning to eliminate field contaminants/surface pesticides.

- Hot-Air Dehydration: Gradual drying (≤7.5% moisture) to maximize shelf life and prevent internal browning.

- Quality Inspection: Each batch sampled according to ISO/GB standards for defect rates, size uniformity, and kernel color.

- Grading & Packing: Automated weigh-filling, vacuum packaging into food-grade cartons or polymer sacks.

- Storage & Logistics: Cold-chain staging; traceability tagging via QR/barcode integration.

Compared to lower-grade or hand-processed bulk walnuts, this production line ensures the lowest impurity rates (<0.2%), ideal for peanuts/walnut snack OEMs, health food packaging, and international supermarkets.

Technical & Application Advantages vs. Competing Wholesale Walnuts

- Higher Kernel Ratio (≥58%): Maximizes edible output, lowering per-kg kernel cost for processors compared to Chandler or Yalova type.

- Shell Thinness (1.0–1.2mm) but High Impact Resilience: Reduces shipping weight, allows easy shelling by consumer or machinery (tested: 10 N pull vs. Chandler’s 8 N fracture).

- Uniform Grading: Over 92% meet size/shape specification; low chance of rejects in vending, retail, niche bakery.

- Longer Shelf Life: Moisture and defect control enable stable warehouse storage for 12–18 months.

Application Scenarios & Typical Customer Cases

- Importers/Distributors (Europe, MENA): Large-scale wholesalers value Xin 2 in-shell walnuts for reliable supply, traceable lot coding, and high market acceptance (German and Italian importers reported 13% year-over-year sales growth for Xinjiang-sourced nuts in 2023 – source: Agrotrade Monitor).

- Snack OEM/Contract Packagers: Uniform size and shell strength allow high-speed cracking and automated retail pouch packing with minimal breakage.

- Health Food Retail Chains: Promote "whole walnuts for sale" with “hand-crackable, sweet kernel, non-bitter taste” as a selling point, matching consumer health preferences.

- Industrial Food Plants: Consistent kernel output (low shrinkage after shelling) supports mass production of walnut powder, nut mixes, and bakery inclusions.

- Export Processing Zones: Certified batches facilitate tariff/clearance for EU, India and Middle East food safety regimes (ISO, HACCP, FDA accepted).

Case Study: German Retailer 2023 – Switched to Xin 2 grade for organic section in June 2023: Reported customer satisfaction index rose by 18 points, and faulty delivery rate fell below 0.9% over 6 months.

Technical Comparison: Xin 2 vs. Mainstream In-Shell Walnuts

| Xin 2 (Xinjiang) | Chandler (California) | Yalova (Turkey) | |

|---|---|---|---|

| Shell Thickness | 1.0–1.2 mm | 1.2–1.5 mm | 1.3–1.6 mm |

| Kernel Yield | 58–59% | 51–54% | 46–48% |

| Defect Rate | <2% | 2–3% | 3–4% |

| Common Defect | Rare shrivel/spot | Bitter kernel streak | Cavity darkening |

| Certifications | ISO22000, HACCP, Halal, FDA | USDA, FDA | ISO22000 |

| Typical Moisture (%) | ≤7.5% | ≤8.0% | ≤8.5% |

| Size Uniformity | High (>92%) | Medium | Medium |

Customization, Delivery, Warranty & Service Support

- Custom Grading: Size, shell color and packaging can be tailored (32–34mm, 34–36mm, 36–40mm; carton, sack, vacuum-packed on request).

- Private Label & OEM Packing: Flexible packaging/labeling to match client’s retail/OEM channel needs (FBA/retail/foodservice).

- Delivery: FOB/Qingdao, EXW/Urumqi or CIF offered; typical production lead time: 7–10 working days after order confirmation for bulk, 2–3 days for samples.

- Quality Guarantee: All whole walnuts for sale covered under 12-month shelf-life warranty, with aftersales refund/replace policy.

- Customer Support: Dedicated account manager, live chat and 24-hour email/phone support in English/Russian/Arabic.

- Compliance: Full lot traceability, conformity certificates (ISO22000, Halal, HACCP, FDA-compatible).

[1] International Nut & Dried Fruit Council (INC). Walnuts Market Report 2023. INC Data

[2] Agrotrade Monitor, 2024. “Walnut Import Trends in Germany & India.” Agrotrade Forum

[3] “China Xinjiang In-Shell Walnuts: Technology and Export Certification”, Food Engineering Review, 2023. Springer Journals

[4] Industry QA—Walnuts in Shell Grading and Testing Guide, 2022, QualityWalnuts.com

[5] UNECE DDP-01, “International Standards for Walnuts in Shell”, UNECE

Post time:Jul . 28, 2025 07:01