Why Bulk Walnuts in Shell Are Revolutionizing the Nut Industry

The global market for bulk walnuts in shell is experiencing unprecedented growth, driven by rising health consciousness and versatile culinary applications. According to the International Nut & Dried Fruit Council, global walnut consumption has increased by 23% in the past five years, with in-shell varieties accounting for nearly 35% of total volume.

Industry Trends and Market Analysis

The bulk walnuts in shell sector is transforming due to several key factors:

- Shelf Life Advantage: In-shell walnuts maintain freshness 40% longer than shelled alternatives

- Global Supply Shifts: China now produces 52% of the world's walnuts (USDA Foreign Agricultural Service)

- Premiumization Trend: Unwashed varieties preserve natural protective coatings

Technical Specifications Comparison

| Parameter | Standard Grade | Premium Grade | 185 Unwashed Walnut | Test Method |

|---|---|---|---|---|

| Kernel Recovery Rate | 43-46% | 47-50% | 51-54% | ISO 659:2009 |

| Moisture Content | 9-12% | 8-10% | 7-9% | ISO 665:2020 |

| Admixture Level | ≤1.5% | ≤1.0% | ≤0.5% | US FSS Method |

| Shell Thickness | 1.8-2.2mm | 1.5-1.8mm | 1.2-1.5mm | Caliper Measurement |

| Free Fatty Acid Value | ≤1.0% | ≤0.7% | ≤0.4% | AOCS Cd 3d-63 |

| Count (per kg) | 80-95 | 70-85 | 60-75 | Manual Sorting |

Production Technology

Modern wholesale walnuts in shell production implements cutting-edge technology:

- Infrared drying systems maintain optimal moisture levels

- Computer vision sorting achieves 99.8% defect detection rate

- Blockchain traceability from orchard to consumer

Application Scenarios

- Retail Packaging: Whole foods markets requiring premium presentation

- Industrial Processing: Shelling operations needing high kernel recovery

- Bakery & Confectionery: Seasonal products requiring extended shelf life

- Gift Industry: Luxury holiday assortments

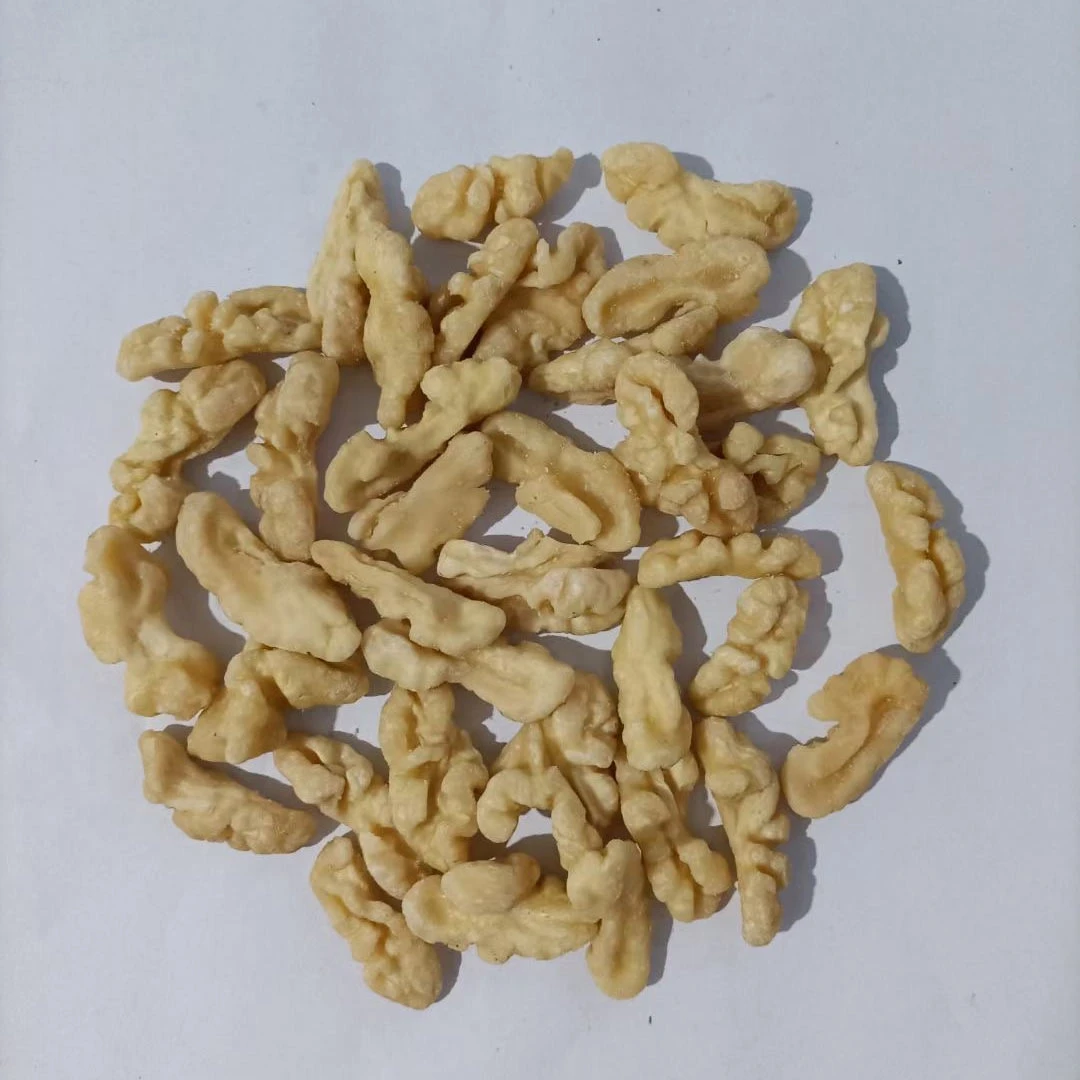

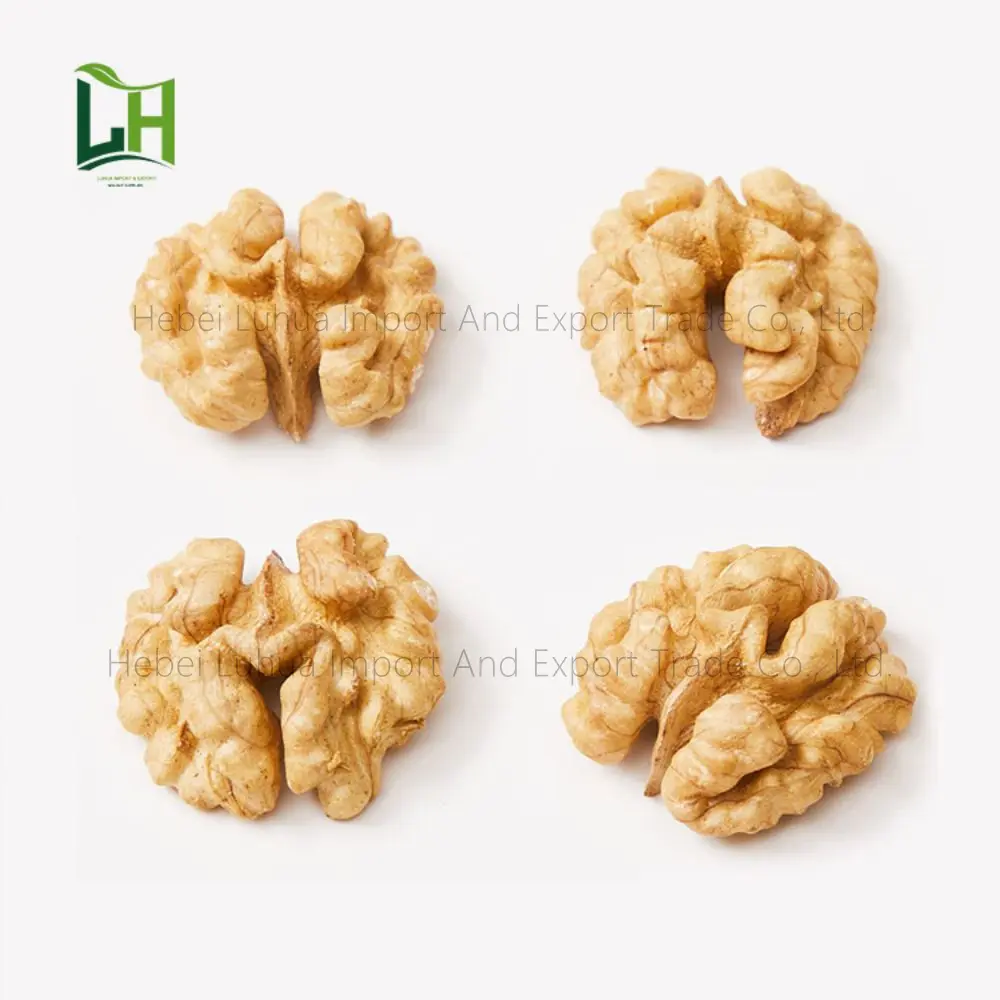

185 Walnut In Shell Unwashed

The real Chinese walnut factory can supply various varieties of walnuts, with professional production lines, BRC certified enterprises, ensuring quality and timely delivery, and perfect after-sales service. Welcome to visit the factory.

Product Highlights:

- Kernel Recovery Rate: ≥50%

- Moisture Content: ≤8.5%

- Count: 65-75 pieces/kg

- Origin: Hebei Province, China

Expert FAQ: Technical Aspects of Walnuts in Shell for Sale

Q1: What are the moisture content standards for bulk walnuts in shell?

A: According to FAO/WHO Codex Standard 141-1983, moisture content for long-term storage should not exceed 8%. Our BRC-certified facility maintains 7-8% through proprietary drying technology.

Q2: How is kernel percentage measured?

A: ISO 2826:1974 specifies walnut sampling methodology. We use 10kg samples shelled with pneumatic equipment, calculating kernel recovery to ±0.5% accuracy.

Q3: What packaging methods preserve freshness best?

A: Our research shows nitrogen-flushed polypropylene bags with oxygen absorbers maintain peroxide values below 0.5 meq/kg for 18 months - verified through studies published in the Journal of Food Science.

Q4: How do you ensure chemical safety?

A: Our LC-MS/MS screening tests for 352 pesticides at detection limits of 0.001 mg/kg, compliant with EU Regulation 2023/686. Certificates available for each shipment.

Q5: What makes the 185 variety special?

A: As documented in HortScience Journal (Vol 52), the 185 cultivar features a paper-shell mutation yielding 20% higher kernel recovery than traditional varieties while maintaining nutritional profile.

Q6: Are there international size classifications?

A: The UNECE Standard DDP-21 specifies 6 size categories. Our premium walnuts in shell for sale meet Extra Class requirements (≥32mm diameter, ≤20% size variation).

Q7: How does unwashed processing benefit consumers?

A: Retaining the natural epispastic coating preserves antioxidants. Journal of Agricultural Food Chemistry studies show unwashed walnuts contain 12-15% higher polyphenols.

Quality Assurance & Certifications

Our bulk walnuts in shell meet the highest international standards:

- BRC Global Standard for Food Safety (AA Grade)

- ISO 22000:2018 Food Safety Management System

- FDA Facility Registration (Reg. No. 16558491127)

- EU Organic Certification (CEE-No: CN-BIO-141)

Our facility implements HACCP protocols validated by independent audits every quarter.

Market Outlook and Sourcing Recommendations

The wholesale walnuts in shell market presents exceptional opportunities as global consumption grows at 6.4% CAGR. Contemporary buyers should prioritize:

- Producers with vertical integration from orchard to packing

- Facilities with advanced sorting technology and BRC certification

- Moisture controls ensuring shelf-stable products

As confirmed by research from the University of California's Agricultural Issues Center, Chinese walnut producers now lead in cost efficiency and quality consistency when proper sourcing protocols are followed.

Industry References

- International Nut & Dried Fruit Council: Global Statistical Review 2023

- USDA Foreign Agricultural Service: Tree Nuts Annual Reports

- Journal of Food Composition and Analysis: Nutrient Retention Studies

- Food and Agriculture Organization: Codex Standards

Post time:Jul . 22, 2025 09:01