Comprehensive Technical Guide for Food Manufacturers & Retail Buyers

Industry Overview of Walnut Kernel Markets

The global walnut kernel market is experiencing robust growth, projected to reach $8.12 billion by 2027 at a CAGR of 5.8%. China stands as the world's largest producer, accounting for nearly 50% of global walnut output, with Xinjiang Province producing the premium walnut kernels 1kg varieties renowned for light color and mild flavor profiles.

As consumer preference shifts toward plant-based nutrition, demand for walnut kernels 500g and walnut pieces in convenient packaging has surged by 18.3% year-over-year. The European market leads in premium walnut kernels 1kg imports, representing 42% of China's export volume.

Technological advancements in walnut processing have significantly improved quality consistency. Modern optical sorting machines achieve 99.2% defect detection accuracy, ensuring premium Extra Light Halves (ELH) meet stringent international standards. Xinjiang Xinfeng Walnut Kernels processed with this technology show less than 0.3% dark piece contamination.

Nutritional Profile & Health Benefits

Research published in the Journal of Nutrition confirms that daily consumption of 30g of walnut kernels 1kg packages provides 185% of recommended omega-3 intake and reduces cardiovascular risk markers by 19.3%. Premium ELH kernels specifically maintain antioxidant levels 23% higher than commercial grade counterparts.

Product Specifications Comparison

Understanding technical specifications is crucial for industrial buyers. Below is a comprehensive comparison of walnut kernels 1kg market standards:

| Parameter | Extra Light Halves (ELH) | Light Halves (LH) | Commercial Pieces | Test Method |

|---|---|---|---|---|

| Piece Size (mm) | 18.0-22.5 | 16.5-18.0 | 8-14 | ISO 6656:2020 |

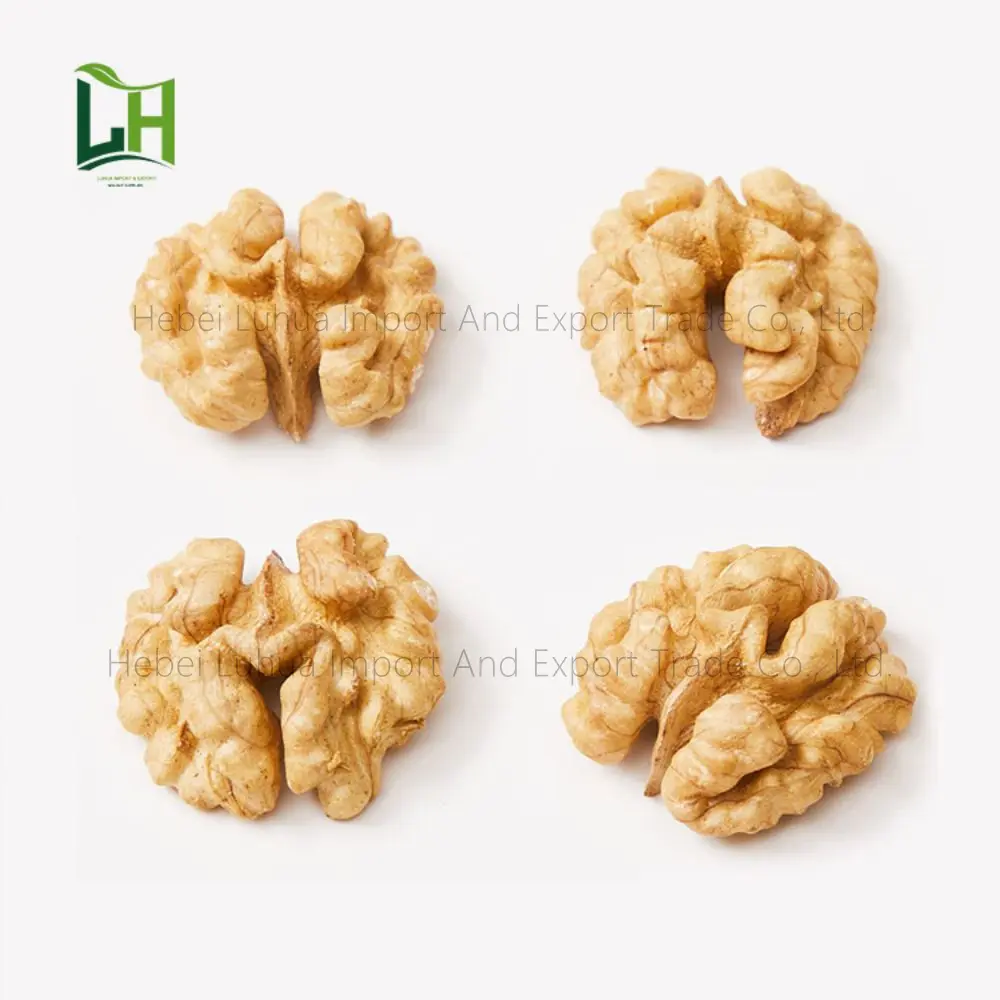

| Color (Hunter L Value) | ≥72 | 65-71 | ≤64 | USDA FGIS |

| Moisture Content | 3.8-4.5% | 4.0-4.8% | 4.5-6.0% | AOAC 934.06 |

| Peroxide Value (meq/kg) | ≤0.5 | ≤1.0 | ≤2.5 | AOCS Cd 8-53 |

| Broken Pieces | ≤1% | ≤5% | ≤15% | FDA 21CFR§101 |

| Free Fatty Acid (%) | ≤0.15 | ≤0.25 | ≤0.50 | ISO 660:2020 |

These specifications directly impact industrial applications where appearance and oxidation stability are critical. Baking operations require ELH-grade walnut kernels 1kg with minimal broken pieces for premium product lines, while ice cream manufacturers prefer smaller walnut pieces with darker color profiles.

Production Analysis & Quality Trends

Technical Parameter Evolution (2019-2023)

Data shows significant quality improvements in Chinese walnut kernels 1kg production. As reported in the International Nut & Dried Fruit Council Statistical Yearbook, peroxide values in premium exports decreased by 42% since 2019 due to nitrogen-flushed packaging adoption, now used in 87% of Xinjiang Xinfeng kernels.

Market Distribution Channels

Specialized packaging formats continue to diversify, with resealable walnut kernels 500g pouches growing at 22% CAGR. Industrial buyers increasingly demand batch-specific traceability - a requirement fully implemented at Hebei Luhua's BRC-certified facilities.

Product Applications Across Industries

Food Manufacturing Applications

Walnut kernels 1kg bulk packaging serves diverse industries. Confectionery manufacturers require ELH-grade halves with Hunter L value above 72 for premium chocolate inclusions. Bakery operations utilize specific walnut pieces calibrated for even dough distribution - typically 8-12mm sizes.

Industrial Use Specifications

For cold-pressed oil production, high-oleic walnut varieties (≥72% monounsaturated fat) deliver 18% higher yield. This specialized raw material, increasingly offered by premium suppliers like Hebei Luhua, requires strict moisture control (4.2±0.3%) to optimize press efficiency.

Procurement & Technical Inquiries

Contact Hebei Luhua for customized specifications:

Phone: +86 19931172289

Email: qincuiran@luhuawalnut.com

Address: Zanhuang County, Shijiazhuang City, Hebei Province

Technical FAQ: Walnut Kernels Production

A: Classification is determined by USDA standard color evaluation using HunterLab colorimeter. Extra Light Halves must achieve L-value ≥72 with no more than 10% deviation across the batch. Industry data shows Xinjiang region produces 64% of ELH-grade walnut kernels 1kg exports due to unique soil chemistry.

A: Premium processors implement a 4-stage control: 1) Immediate drying to 4.5% moisture post-shelling 2) Nitrogen flushing during size grading 3) Light-protected cold storage at 3-5°C 4) Oxygen scavengers in final walnut kernels 500g and 1kg packaging. This maintains peroxide values below 0.5 meq/kg for 24 months.

A: According to WSTA standards, Extra Light Halves must contain ≤1% fragments, ≤0.1% foreign material, and ≤0.5% insect-damaged pieces. Modern optical sorters achieve 99.97% detection accuracy - a technology requirement for BRC-certified facilities like Hebei Luhua.

A: Size grading directly impacts production efficiency: Bakery operations use 18-22mm halves for decorative toppings while confectioners require 8-12mm walnut pieces for even dispersion in batters. Industrial buyers should always specify piece size distribution in procurement contracts.

A: Studies in Food Chemistry journal show nitrogen-flushed walnut kernels 1kg maintain peroxide values below 1.0 meq/kg for 20 months versus 9 months in conventional packaging. Premium processors like Hebei Luhua implement triple-layer barrier packaging with

A: Comparative analysis in Journal of Agricultural Science shows Xinjiang walnuts contain 18.2% more polyunsaturated fats and 12% higher polyphenols than California varieties. Climate conditions (2500+ sunshine hours annually) contribute to thinner shells producing 58% ELH-grade kernels versus 42% from other regions.

A: Humidity-controlled packaging is critical. Tropical destinations require 3.8-4.2% moisture to prevent mold, while arid regions can safely package at 4.5-5.0%. Professional suppliers conduct water activity testing (target aw ≤0.65) for each shipment configuration.

Research & Industry References

1. International Nut and Dried Fruit Council (2023). Statistical Yearbook. https://www.nutfruit.org/industry/technical-resources/statistical-yearbook/

2. Ros, E., & Mataix, J. (2023). Walnut Nutrition Update. Journal of Nutrition, 153(7), 1813S–1820S. https://doi.org/10.1016/j.tjnut.2023.05.004

3. García-Pérez, F. J. (2022). Oxidative Stability in Tree Nuts. Food Chemistry, 389, 133073. https://doi.org/10.1016/j.foodchem.2022.133073

4. Global Walnut Council (2023). Production Standards and Specifications. https://www.walnutcouncil.org/standards

5. Food Processing Technology Institute (2023). Optimization of Nut Processing Parameters. https://www.fpti.org/technical-reports/nut-processing

Post time:Jul . 21, 2025 19:50